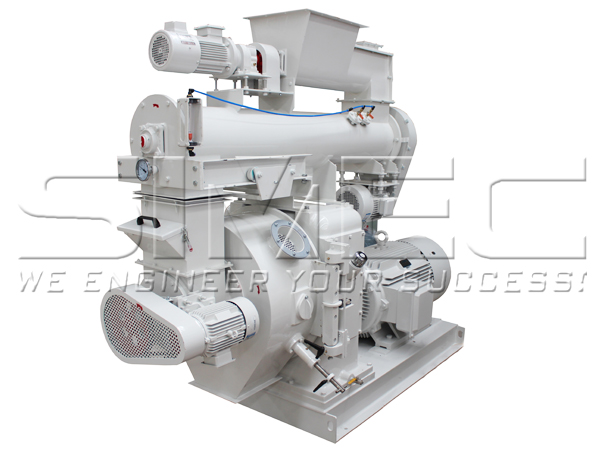

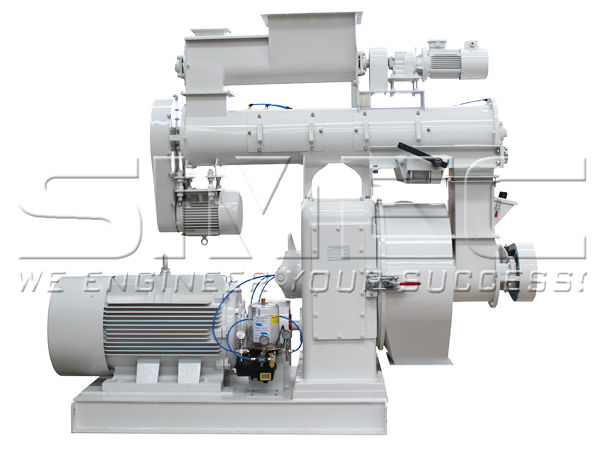

SPM420 Biomass Pellet Mill

Introduction:

SPM series high-grade pellet mill is the main item of equipment for producing wood pellet with application to large and medium scale wood pellet plant.

The machine features compact structure, fine appearance, low noise, high output with low power consumption, it is convenient in operation and reliable in performance.

The machine can be fitted with dies of Ø6 or Ø8 hole diameter, which can be chosen by user according to requirements.

The machine adopts frequency conversion speed-adjusting motor for feeder and LLL large door conditioner access, with axial liquid addition.

Feeder is fitted with strong magnetic safety device, press overload protection device and external discharging mechanism.

SPM420 Biomass Pellet Mill

Parameters:

| No. | Model | SPM420 | |

| 1 | Output | 0.8-1.2t/h | |

|

2 |

Power |

Main Motor | 90/110KW |

| Screw feeder | 1.5KW | ||

| Conditioner | 3KW | ||

| Force feeder | 1.5 KW | ||

| 3 | Die ID | Ф420mm | |

| 4 | Effective Width of Die | 83/93mm | |

| 5 | Die Rotational Speed | 138rpm | |

| 6 | Feeder Rotational Speed | 12-90rpm | |

| 7 | Pellet Specification | Ф6~Ф12mm | |

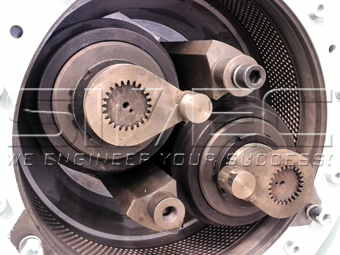

| 8 | Roller Number | 2 | |

| 9 | Roller OD | Ф206mm | |

| 10 | Pellet Shaping Rate | ≥95% | |

| 11 | Pellet Powdering Rate | ≤10% | |

| 12 | Pellet Stability in Water | ≥20min | |

| 13 | Noise | ≤70dB(A) | |

| 14 | Working Temperature of Die | ≤165 C | |

| 15 | Overall Dimension |

2777×1387×2028mm

|

|

SPM420 Wood Pellet Mill

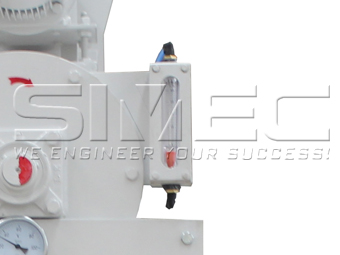

1. Automatic Lubrication system

SPM420 pellet mill is equipped with automatic lubrication system, which save the cost and labors of lubricating, to know more details and working principles about pellet mill lubrication system, please read the blog: CENTRALIZED AUTOMATIC LUBRICATION SYSTEM FOR WOOD PELLET MILL.

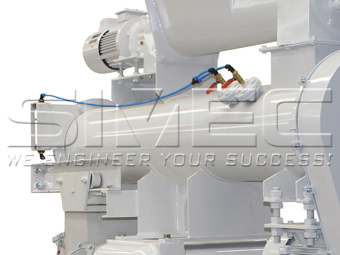

2. Ring Die Lifting Installation System

SPM420 has ring die lifting installation system, the system can realize the automatic installation of ring dies. A removable steel frame is fixed at the bottom of the conditioner, steel wire convolve on it can tie on a ring die and lift it to the proper position.

SPM series pellet mill adopts the technology of integrated main shaft. The roller support rods are forged together with main shaft. So it avoids any vibration fundamentally. The material has also been improved to be 40CrMn. Both of the performance and life span is guaranteed. Benefits of this design can be known at the blog of INNOVATION OF SPM520 WOOD PELLET MILL.

4. Water Adding System

At conditioner there is a water pipe, it can add water into the raw material to adjust the moisture to the proper content for better pelletizing. The pipe is connected on a dial gauge that shows the volume of water, making it easy to be detected and controlled.