Centralized Automatic Lubrication System for Wood Pellet Mill

SIMEC has established more than 85 complete biomass pellet line projects all around the world, including wood pellet, palm EFB pellet and other biomass pellet plants. Nearly 600 sets of pellet mills had been exported, SIMEC pellet mills are equipped with automatic lubrication system at factory, for saving the cost and labor of lubricating.

II. Superiorities of Centralized Automatic Lubrication System

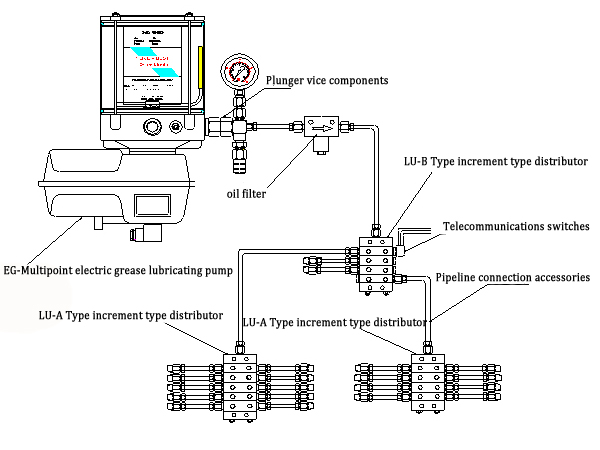

SIMEC progressive centralized lubrication system, EG-multipoint electric grease lubricating pump with 1-8 pump unit at the same time; the pump unit can be directly connected to the lubrication points for 2 roller bearings and the main shaft bearing. It can also be used with distributor. Design of pump unit and EG series pump is firm and durable, can work normally at -35 ℃ to +75 ℃ environment. Particularly suitable for the lubrication and seal.

III. Principle of operation:

Motor through the worm gear for driving the eccentric wheel, the eccentric wheel and the pump unit with the plunger reciprocating motion, suction and pumping oil, and the integrated one-way valve in the pump unit can prevent grease from the main oil is pumped back to the tank. The oil scraping plate rotation can be pressed into the suction zones lubricant pump unit, and can effectively eliminate bubbles.

Centralized Automatic Lubrication System

IV. How to Choose Suitable Lubrication Grease

Main factors to consider the following selection of lubricating grease are:

Speed: two friction relative speed is high, the formation of dynamic pressure oil film role more strong. It should be low viscosity lubricating oil or grease with large cone penetration.

Load size: the greater the load, the higher oil viscosity; and vice versa.

Working temperature: usually oil model (000#-2#) is the test model of 20℃ under normal temperature.

Oil at different temperature selection principle is: 20℃ with 2# oil, 10℃ - 20℃ with 1# oil, 0℃ - 10℃ with 0# oil, 0℃ should choose 00# or 000# grease.

Technical parameters of suggested lubrication grease

Rated pressure: 250bar(25MPa);

Pump displacement: 0.8、1、、1.5、2、2.5、5ml/min;adjustable;

Tank volume: 4L、6L;

Power: 70W;

Levels of protection: IP65

(The suggestion according to the change of environmental temperature, the timely adjustment of the medium viscosity)

V. SIMEC Lubrication Grease

We suggest customers to use U.K Express Thounder HP-2 high-temperature synthetic grease or other grease with similar performances. Detail parameters can reference to the parameters listed below:

| Type | HP 2# |

| Appearance | Blue grease |

| Cone penetration of working (1/10mm) | 286 |

| Dropping point (℃) | 290 |

| Cone penetration of enhanced working | 291 |

| Corrosion (T2 copper sheet, 100℃, 24h) | qualified |

| Extreme pressure property (method of ladder, Ken) OK value, N | 180 |

VI. The scope of warranty

Under normal condition, the main machine warranty period, we will repair free of charge.

Any of the following circumstances, without free repair:

⑴ Due to failure caused by external impact, inadequate protection, such as the abnormal voltage;

⑵ Failure to comply with the rule of "maintenance", installation damage caused by improper operation;

⑶ Use the oil properly, if there are special additives in grease or non-designated grease (extreme pressure lithium base grease) damage;

⑷ Adjust the lubrication of time, will not cover properly installed reduction, or loss caused by damage control system.

With professional technology and rich practical experience, SIMEC devote to provide quality products, better aftersales services, fluent production process and higher economic benefits to the customers! Please contact us to get more detailed technical information of the automatic lubrication system.