Sugar Cane Bagasse Pellet Plant

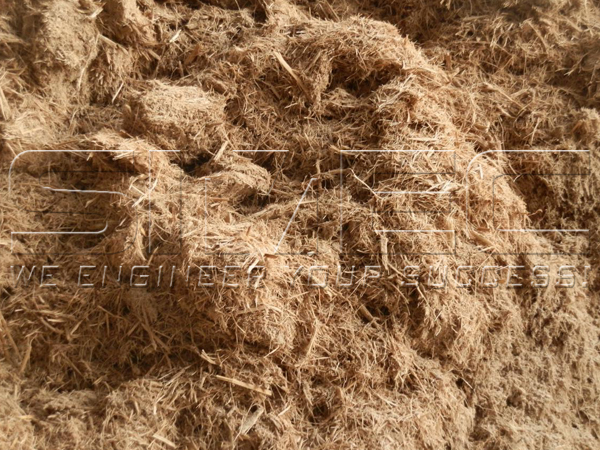

Bagasse is the fibrous matter that remains after sugarcane or sorghum stalks are crushed to extract their juice. As one of the main by-products, for each 10 tons of sugarcane crushed, 3 tonnes of bagasse is generated by the sugar factory.

Sugar factory

Sugar Factory By-products

A typical chemical analysis of bagasse might be (on a washed and dried basis):

Cellulose 45–55%

Hemicellulose 20–25%

Lignin 18–24%

Ash 1–4%

Waxes <1%

Dried Sugar cane fiber

Sugar Cane Fiber

Except for being used as the raw material for producing pulp, paper, board, the bagasse is often converted into pellets, which are used as fuel and cattle feed.

Bagasse Pellet Fuel

Bagasse pellets are treated as one of the main biomass energy in the biomass pellets market. Comparing with other biomass raw materials, the bagasse contains around 20% lignin, which can help the pellet forming. Meanwhile, the bagasse pellet has higher calorific value at 4461 kilocalorie per kilogram (kcal/kg) (or 4.5 kilowatt hours per kg), and lower ash content at less than 6.4%, compared with other biomass pellets.

| Bagasse Pellet | Rice Husk Pellet | Corn Straw Pellets | |

| Total Moisture | 3.5% | 14% | 11% |

| Ash Content | 6.1% | 8% | 7% |

| Total Sulfur | 0.12% | 0.1% | 0.4% |

| Gross Calorific Value | 4461 Kcal/Kg | 3500 Kcal/Kg | 3700 Kcal/Kg |

The bagasse pellets can be used as the solid fuel for their own boilers of the sugar factories, or be exported to the target markets. In Southeast Asia, plenty of bagasse pellets are exported to South Korea as the co-firing fuel for the power plants. China has also started importing bagasse pellets in quantity for the consumption of the coastal biomass power plant. Each power plant can consume at least 10000 tonnes of pellets per month.

Bagasse Pellet

Bagasse Pellet Fuel

Bagasse Pellet

Bagasse Pellet Fuel

Report of analysis for sugarcane bagasse pellet:

| CLIENT | SIMEC Pellet Union |

| THE FOLLOWING SAMPLE (S) WAS/WERE SUBMITTED AND IDENTIFIED BY CLIENT AS : | |

| TYPE OF SAMPLE | SUGARCANE BAGASSE PELLET |

| DATE OF RECEIVED | December 01,2015 |

| DATE OF ANALYSIS | December 01 up to 03, 2015 |

| TEST REQUIRED | Total Moisture, Ash Content, Volatile Matter, Fixed Carbon, Gross Calorific Value, Nitrogen. |

| DESCRIPTION OF SAMPLE |

From: Pellet Weight/ Volume: ± 5Kg Packing: Unsealed carton bag |

|

SAMPLE IDENTIFICATION (STATED BY CLIENT) |

Code: PELLET AMPAS PRODUKSI PABRIK GULA TRANGKIL, PATI |

We have tested the sample(s) submitted and the following results were obtained:

| Parameters | Unit |

AR (As Received ) |

DB (Dry Basis) |

Test Method |

| Total Moisture | % wt | 3.5 | - - - | ASTM D 2961 - 11 |

| Ash Content | % wt | 6.1 | 6.4 | ASTM D 3174 - 12 |

| Volatile Matter | % wt | 77.3 | 80.1 | ASTM D 3175 - 11 |

| Fixed Carbon | % wt | 13.1 | 13.5 | ASTM D 3172 - 13 |

| Total Sulfur | % wt | 0.12 | 0.12 | PO - BB – 11 |

| Gross Calorific Value | Kcal/Kg | 4305 | 4461 | ASTM D 5865 - 13 |

| Nitrogen (N) | % wt | 0.10 | - - - | ASTM D 5373 - 14 |

A 3TPH sugar cane bagasse pellet project has been established in central Jawa Indonesia. The output pellets would be sold as pellet fuel and cattle feed.

Bagasse Cattle Feed Pellet

Biological treatment of fibrous material is attracting attention of the scientists all over the world. If use bagasse as growth medium for certain fungi and mushrooms, the energy availability would be improved. Further studies are therefore needed for developing a technology suitable for application at farm level.

The bagasse can be manufactured into low cost cattle feed. The chemical composition of bagasse is indicated in the following table and is comparable to cereal straws which are conventionally used for feeding cattle.

Bagasse Feed Pellet

Chemical composition of sugarcane bagasse (% DM)

| CP | CP | EE | Ash | KPE | NDF | ADF |

| 2.86 | 31.76 | 0.80 | 4.76 | 56.82 | 78.60 | 54.36 |

The sugar cane bagasse contains many essential nutrition for the cattle, 44%-16% coarse fiber, 0.7% coarse fat, 1.5% crude protein, etc. The bagasse is very good raw material of the feed for the ruminant animals, such as cattle, caw, sheep, goat, camel etc.

Considering the low palatability and digestibility of the bulk bagasse, either the correct pre-treatment and effective formulations are necessary for producing the bagasse feed pellets. Based on different formulation and usage, the bagasse would be treated before pelletizing or not. Normally the pretreatment methods include ferment and steam.

How to Make Bagasse Pellets

Either for making fuel pellets or feed pellets, the bagasse need the following preprocessing:

• Moisture Reduction

The bagasse need to be dried to 15%-18% moisture content in the specialized rotary dryer. The uniquely designed bagasse feeding, discharging system and shovels inside the dryer can prevent the raw material blocking and guarantee the evenness of the target moisture content of the bagasse.

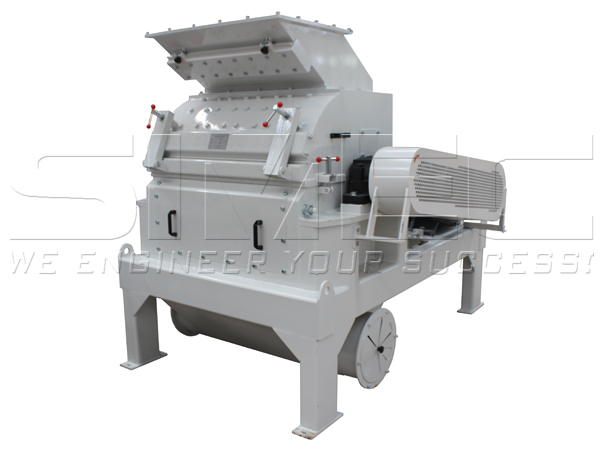

• Size Reduction

The dried bagasse fiber should be crushed in the hammer mill into 3-5 mm bagasse dust, which can be easily conveyed and pressed to 6 mm and 8 mm pellets.

• Iron Removal

Considering the damage to the equipment and unstable quality of the bagasse pellets caused by the iron impurity, three strong magnetic separators are furnished in the bagasse crushing system and bagasse pelletizing system.

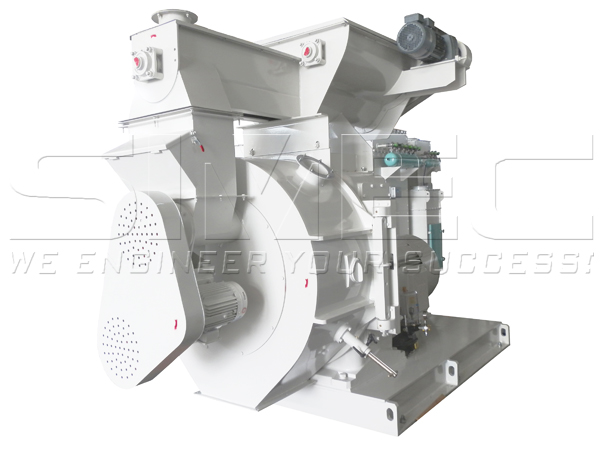

• Pelletizing

The raw material silo, screw feeder and force feeder are fabricated with anti-blockage design;

The cooling system furnished on the pellet mill can cool down the temperature in the pelleting chamber and release the dust from the chamber;

Ring die with specialized design improve the efficiency of the pellet forming;

Main shaft and roller holding rods are forged together as an integration structure, that avoids the vibration of the rollers and extends the service life of the ring die and roller bearings.

• Pellet Cooling & Sifting

Bagasse pellets coming from the pellet mill are cooled in the counter-current cooler, where the pellets temperature can be cooled down by 30-40 degree Celsius;

The dust and unformed stuff is separated by the vibrating or rotary sifter;

• Pellet Packing

Both of jumbo packing and 15-50 kg/bag packing system are available;

Fully automatic packing system is optional.

The above is brief introduction of our solution & technology on cane bagasse utilization. If interested, you're welcome to contact us for further information.