Startup of 3PTH Containerized Pellet Plant in Padang, Indonesia

SIMEC Mobile Pellet Plant

SIMEC MPL Project in Indonesia

After days of installation and commissioning, one of SIMEC Wood Pellet Plant is ready for large-scale production. It is located in a beautiful seaside city, Padang, Indonesia. Usually, installation and commissioning work of containerized pellet plant is able to be finished within 2 weeks. Unfortunately, the frequent rain in the mountain area delayed our pace and extended it into 4 weeks.

Install covers to cope with rain in mountain area

MPL installing on site

This is a 3TPH Containerized Pellet Plant which has better mobility and adaptation in the wild. It’s located in a mountain area and nearby saw mills which is the material source for this pellet project. The nearest saw mill next door is able to supply 15~20 tons of wooden waste per day and it’s able to support 5~7 hours production of 3TPH containerized pellet plant.

The saw mill next door

Wood logs at padang

Based on complete production processes: Chipping-Crushing-Drying-Pelletizing-Cooling, it’s able to process high moisture content materials and big size materials.

On site, the raw material is sawdust on storage and fresh wooden offcuts. Abundant raw materials nearby reduce the delivery cost for pellet plant extremely.

Plenty of sawdust at storage

Wood offcut

Considering working in the wild, the entire system is powered by a 500kw genset. Even the surrounding material of this saw mill runs out, this entire system with genset is able to be delivered to another saw mill by trucks.

Entire containerized pellet plant and the diesel tank & genset

Genset and control distribution box

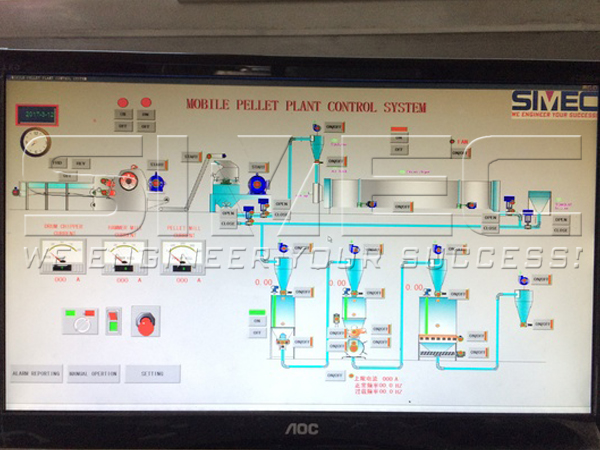

Benefit from a remote operation system and CCTV, the operators are able to operate the entire system in the office. All of the connections and cables were obligated in SIMEC workshop, so we just lift the office container into right position and did an easy connection job, the remote operation system is able to work immediately.

Lifting of office container

Office container remote operation system and CCTV

Interface of entire remote operation system

Wooden offcut is treated by burning

Welcome for your inquiry if you are involved in a similar situation. SIMEC will offer a complete mobile solution and fixed type solution as per your detail requirements and materials. Also we can offer technicians to direct installation and production on site.

We engineer your success!