Palm EFB Powder and Slurry Project in Malaysia

SIMEC palm EFB powder and slurry production line delivered to Malaysia has been in commercial operation since March 2022, after fulfilling all performance guarantee parameters in January 2022 as planned.

The innovative palm EFB powder and slurry plant integrates dry pulverizing system and wet milling system. It is designed to convert 100-150 kg/hour of palm EFB fiber into wet slurry product. The production line features flexible processing capacity and dynamically adjustable production fineness.

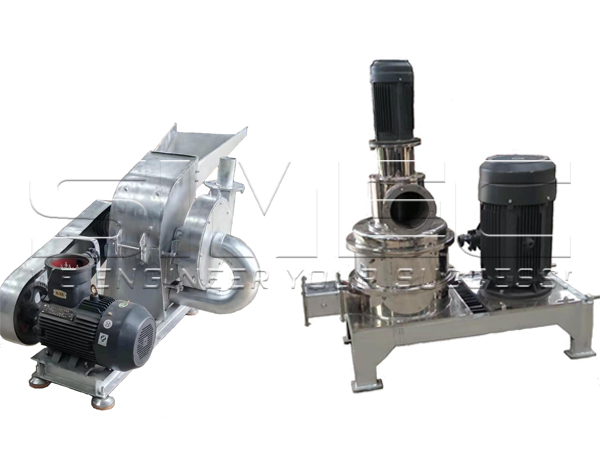

The dry pulverizing system adopts two stage processing technique, presenting by ultra fine pulverizing machine integrated with coarse grinder. Palm EFB fiber with a length of 10-15 cm is sized into short fiber by coarse grinding machine then be pulverized into fine powder. Palm EFB pulverizing machine adopts pneumatic screen-free mechanism. Fine particles flow up and leave the pulverizer through top outlet. Specially designed grading impeller separates the bigger particles and enable them to be pulverized again till qualified. Fineness of output powder can be adjusted within certain range without stopping the machine. There’s no dusty emission throughout the pulverizing process.

The wet milling system is designed to make Palm EFB slurry. It is a tailored system, including agitating tank, screw pump, piping valves and colloid mill, etc. The dry EFB powder is sufficiently blended with warm water and other additives in the agitating tank. Then the well blended feedstock is pumped into the colloid mill and be milled to be homogenized bio-slurry product. The fineness of bio-slurry can be dynamically adjusted on colloid mill.

All the components in contact with biomass material are made of SUS304 stainless steel. Control cabinets and electric motors are explosion-proof up to CNEX and IECEx.

SIMEC undertook project consulting, engineering design, equipment manufacturing and delivery. The client completed the erection and commissioning work by SIMEC remote technical support. With the advance of the application research of palm EFB based bio-slurry, larger EFB pulverizing plant will be built up accordingly.

SIMEC have extensive experience in making dry powder and wet slurry from palm EFB fiber. We furnish our clients crafted project solutions and help them create greater value from palm empty fruit bunch.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.