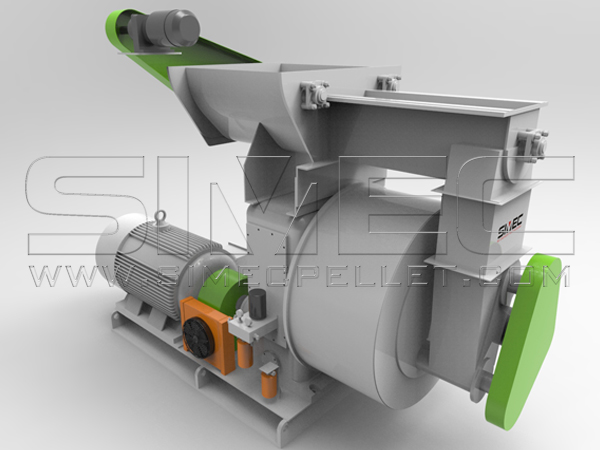

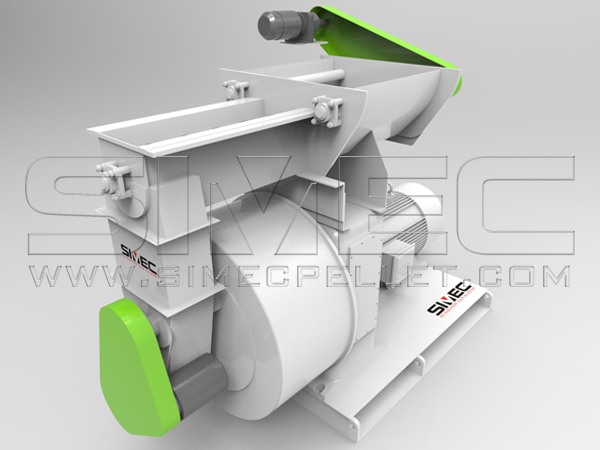

SPM780 Biomass Pellet Mill

SPM780 Wood Pellet Mill

SPM780 Wood Pellet Mill

SPM series high-grade pellet mill is the main item of equipment for producing wood pellet with application to large and medium scale wood pellet plant.

The machine features compact structure, fine appearance, low noise, high output with low power consumption, it is convenient in operation and reliable in performance.

The machine can be fitted with dies of Ø6 or Ø8 hole diameter, which can be chosen by user according to requirements.

The machine adopts frequency conversion speed-adjusting motor for feeder and LLL large door conditioner access, with axial liquid addition.

Feeder is fitted with strong magnetic safety device, press overload protection device and external discharging mechanism.

Auto Oil Cooling and Lubrication System for Main Shaft Bearing and Gearbox

Automated Grease Lubrication System for Roller Bearings

II. MAIN TECHNICAL PARAMETERS OF SPM780

| No. | Model | SPM780 |

| 1 | Output | 2.7-3.5t/h |

| 2 | Main Motor Power | 220/250KW |

| 3 | Feeder Power | 3KW |

| 4 | Die ID | Ф765mm |

| 5 | Effective Width of Die | 155mm |

| 6 | Feeder Rotational Speed | 12-90rpm |

| 7 | Pellet Specification | Ф6~Ф12mm |

| 8 | Roller Number | 2 |

| 9 | Roller OD | Ф370mm |

| 10 | Pellet Shaping Rate | ≥95% |

| 11 | Pellet Powdering Rate | ≤10% |

| 12 | Pellet Stability in Water | ≥20min |

| 13 | Noise | ≤80dB(A) |

| 14 | Working Temperature of Die | ≤165℃ |

| 15 | Overall Dimension |

3667×1870×2505mm

|

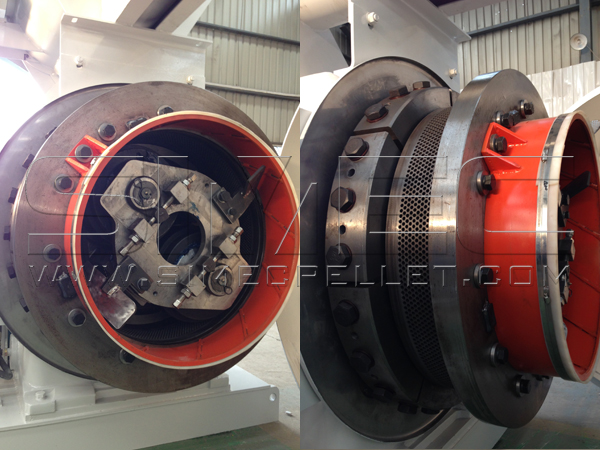

Rotate Gate

Innovated Ring Die Clamping Device

III. MAIN STRUCTURE AND WORKING PRINCIPLE

The sawdust with moisture content not higher than 14% flows into feeder from hopper and proper flow rate is obtained by adjusting the rotational speed of feeder shaft. Then sawdust passes the safety magnet for removing the magnetic impurities and enters the conditioner for conditioning through the stirring of conditioner shaft and mixing with liquid. If liquid additive needs to be added, it can be added to conditioner for conditioning (generally the adding volume cannot be more than 3%). After conditioning, the moisture content of material can be adjusted. Then the sawdust passes the feed chute and finally enters the pellet chamber for pelleting.

SPM780 Wood Pellet Mill Left-front View

SPM780 Wood Pellet Mill Left-rear View

For more information and detail parameters, please download the

INSTRUCTION MANUAL OF SPM780 BIOMASS PELLET MILL.