Do You Know About Torrefaction?

Have you ever heard about torrefaction? It is a mild pyrolysis process that increase the value of biomass. After being torrefied, the material can be pelletized by SIMEC Pellet Mills.

SIMEC has rich experiences in the pelletization of torrefied wood material. Here we will tell you more about torrefaction and torrefied pellets.

Torrefaction Is The Future of Biomass.

Torrefaction Is The Future of Biomass.

What is Torrefaction?

Torrefaction, a process different from carbonization, is a mild pyrolysis process carried out in a temperature range of 230 to 300℃ in the absence of oxygen. This thermal pretreatment of biomass improves its energy density, reduces its oxygen-to-carbon (O/C) ratio, and reduces its hygroscopic nature. During this process the biomass dries and partially devolatilizes, decreasing its mass while largely preserving its energy content. The torrefaction process removes H₂O and CO₂ from the biomass. As a result, both the O/C and the H/C ratios of the biomass decrease. In raw biomass, high oxygen content prompts its over-oxidation during gasification, increasing the thermodynamic losses of the process. Torrefaction could reduce this loss by reducing the oxygen in the biomass. Torrefaction also increases the relative carbon content of the biomass. The properties of a torrefied wood depends on torrefaction temperature, time, and on the type of wood feed.

Torrefaction, a process different from carbonization, is a mild pyrolysis process carried out in a temperature range of 230 to 300℃ in the absence of oxygen. This thermal pretreatment of biomass improves its energy density, reduces its oxygen-to-carbon (O/C) ratio, and reduces its hygroscopic nature. During this process the biomass dries and partially devolatilizes, decreasing its mass while largely preserving its energy content. The torrefaction process removes H₂O and CO₂ from the biomass. As a result, both the O/C and the H/C ratios of the biomass decrease. In raw biomass, high oxygen content prompts its over-oxidation during gasification, increasing the thermodynamic losses of the process. Torrefaction could reduce this loss by reducing the oxygen in the biomass. Torrefaction also increases the relative carbon content of the biomass. The properties of a torrefied wood depends on torrefaction temperature, time, and on the type of wood feed.

Advantages of Torrefaction

Torrefied wood per forms better than original wood (or another biomass) in both gasification and combustion. Major features and advantages of torrefaction are as follows:

- It increases the O/C ratio of the wood, which improves its gasification efficiency.

- It reduces power requirements for size reduction, and improves handling.

- It offers cleaner-burning fuel with little acid in the smoke.

- A fuel gas that has an enhanced heating value may be obtained through gasification.

- Torrefied wood absorbs less moisture when stored.

- One can produce superior-quality biomass pellets with higher volumetric energy density.

Based on these features, we can easily speculate that torrefaction will allow biomass to be used in entrained-flow gasification, direct combustion in a PC-fired boiler, and production of biopellet.

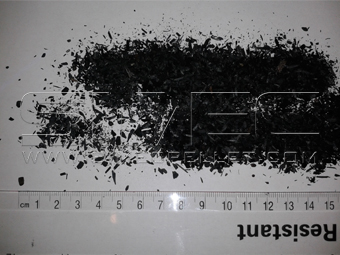

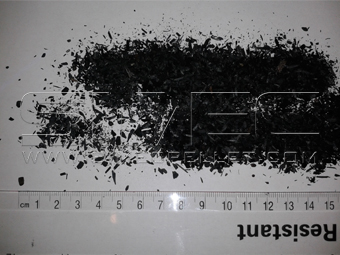

Torrefied Wood Chips

Torrefied Wood Chips

According to the advantages listed above, we can come to the conclusion that torrefaction is an very advanced process of pelletizing.

What are the superiorities of torrefied pellet?

Torrefied Pellet

Torrefied Pellet

The pelletizing process resolves some typical problems of biomass fuels: transport and storing costs are minimized, handling is improved, and the volumetric calorific values is increased. Pelletization may not increase the energy density on a mass basis, but it can increase the energy content of the fuel on a volume basis. For example, while the energy density on a mass basis for raw wood, torrefied wood, wood pellet, and torrefied pellet was 10.5, 19.9, 16.2, and 21.6 kJ/kg (LHV as received basis), respectively, it was 5.0, 4.6, 10.5, and 18.4 GJ/m³, respectively, on a volume basis (Bergman, 2005c). Thus, pelletization of torrefied wood greatly decrease the transportation and handling cost of biomass. Pelletization of torrefied biomass is better than torrefaction of pelletized wood from the standpoint of process energy consumption and product stability.

Torrefied Pellets

Torrefied Pellets

Torrefied pellets are also called Biocoal pellets or Black pellets. More and more power plants have started to burn torrefied pellets that replace coal fuel. This is a good opportunity for biofuel business investors. Torrefaction is reliable technology that will increase the value of biomass. To make pellets from torrefied biomass needs professional pellet mills and experienced engineering team.

SIMEC has been in the research of torrefaction and torrefied pellets for many years. We hope our technology and pellet equipment will help more investors to set up their own torrefied pellet plants.

Torrefied Pellets

Torrefied Pellets

Torrefied pellets are also called Biocoal pellets or Black pellets. More and more power plants have started to burn torrefied pellets that replace coal fuel. This is a good opportunity for biofuel business investors. Torrefaction is reliable technology that will increase the value of biomass. To make pellets from torrefied biomass needs professional pellet mills and experienced engineering team.

SIMEC has been in the research of torrefaction and torrefied pellets for many years. We hope our technology and pellet equipment will help more investors to set up their own torrefied pellet plants.