Force Feeding Hammer Mill

Introduction:

Force feeding hammer mill is improved design based on our factory's dual-motor wood crusher, brings in the domestic and overseas high technology and prevents the problem of plenty dust while crusher working, making the hammer mill more rational and more practical.

Technical Parameters of Force Feeding Hammer Mill

| Type | Hammers Qtty (pcs) | Capacity (t/h) | Milling Fineness (mm) | Main Motors (kw) | Screw Discharger (kw) | Force Feeder (kw) | Dust Extraction Fan (kw) | Hydraulic Device (Kw) |

| DMC-1500 | 66 | 5-8 | 3-15 | 55*2=110 | 7.5 | 5.5 | 2.2 | 4 |

Force Feeding Hammer Mill

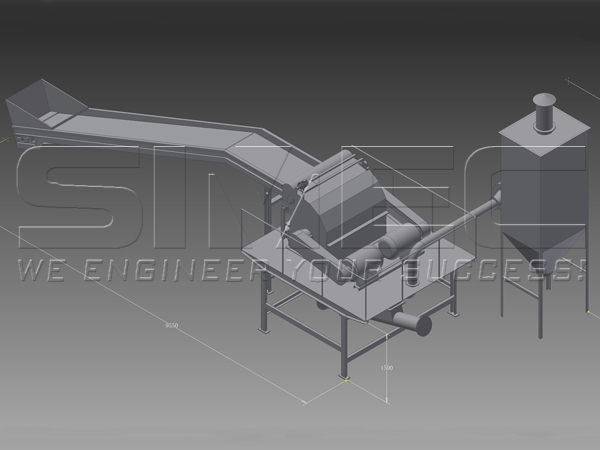

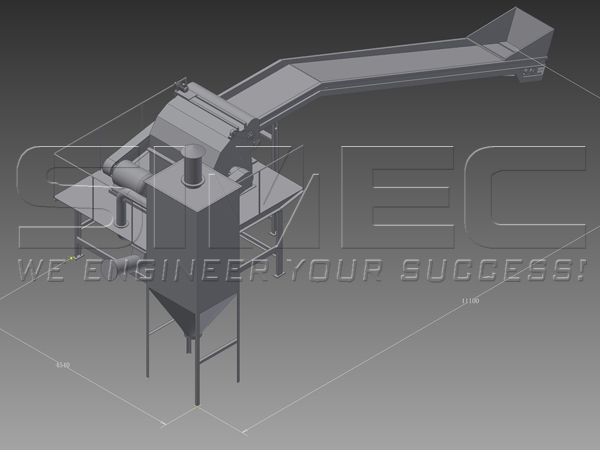

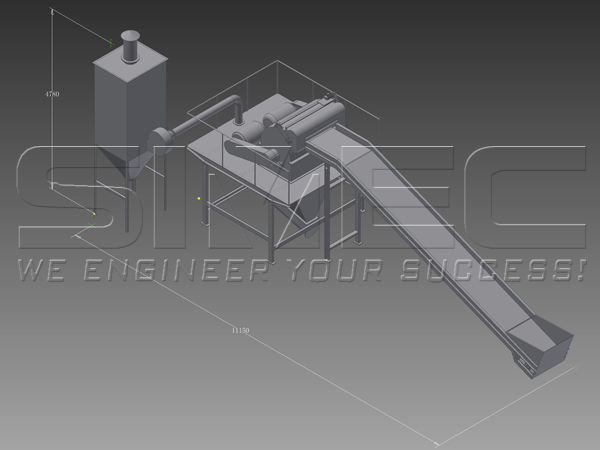

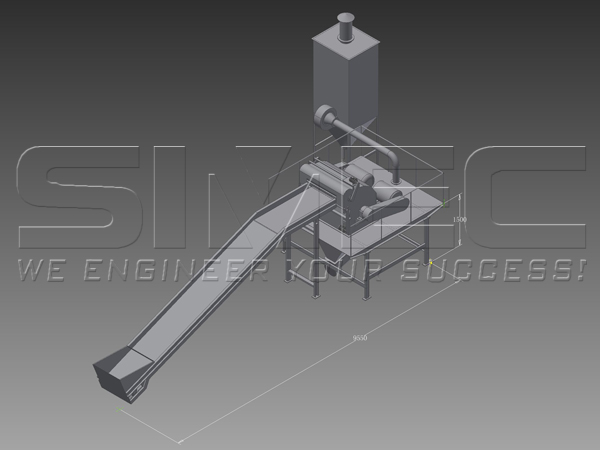

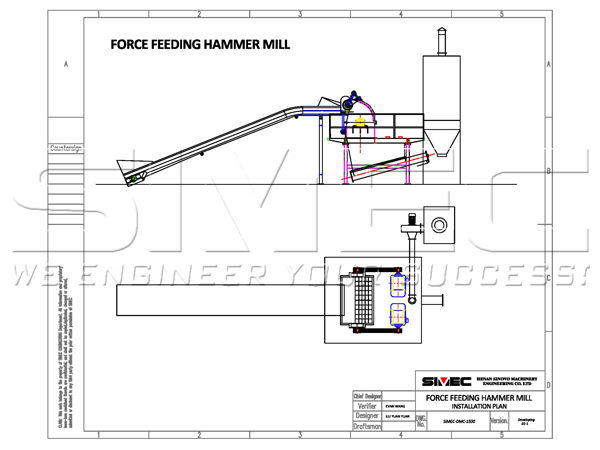

Force Feeding Hammer Mill Diagram

Application:

Force feeding hammer mill is mainly used for processing wood, bamboo and other materials, more suitable to process palm EFB fiber, sugar cane bagasse, waste veneer and other fibrous & loose materials.

Force feeding hammer mill can also be used to crush thatch, corn stalks, sorghum stalk and other fiber stalk-like materials. It can process a variety of tree branches, board slats, wood chips, bamboo, and other woody materials into sawdust, wood filament products in one step, with characteristics of less investment, low energy consumption, high productivity, good economic returns, easy maintenance and other advantages.

Force feeding hammer mill can also be used to crush thatch, corn stalks, sorghum stalk and other fiber stalk-like materials. It can process a variety of tree branches, board slats, wood chips, bamboo, and other woody materials into sawdust, wood filament products in one step, with characteristics of less investment, low energy consumption, high productivity, good economic returns, easy maintenance and other advantages.

Front View of Force Feeding Hammer Mill

Side View of Force Feeding Hammer Mill

Working Principle:

Force feeding hammer mill mainly consists of force feeding teeth roller, crushing device and dust collection system. Fibrous & loose materials can be sent to the crushing device directly without drying, crushed products are sent to the aggregate location by the screw discharger.

Force feeding hammer mill has more complex structure than other hammer-type wood crusher, the appearance are almost the same, consist of the shell, base, pulley, induced draft fan and so on, but the internal crushing chamber is completely different.

Back View of Force Feeding Hammer

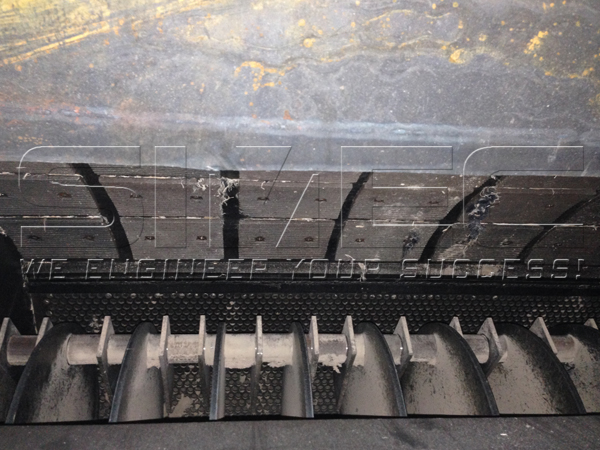

Force Feeding Hammer Mill Blades

Features:

- Force feeding teeth roller to take in fibrous & loose materials, such as sugarcane bagasse fiber, palm EFB fiber, veneer waste, etc.

- Hydraulic top cover opening system which make it easy to open the crusher, then check & maintain hammers and screens.

- High strength hammer knives 10mm thickness, casting blocks fixed inside for material grinding;

- Well balanced crushing rotor is 1500mm wide, equipped with dual 55Kw motors.

- Its screw discharger at bottom conveys materials efficiently, full sealed without dust flee.

- Complete crushing system including strong magnetic feeding conveyor, dust extraction bag filter.

Force Feeding Hammer Mill Outlet

Crushed Wood Materials (screen Φ8mm)

Palm Leaves and Trunk being Shredded

Crushed Palm Leaves and Trunk

SIMEC Force Feeding Hammer Mill Test Run:

Force Feeding Hammer Mill 3D Diagrams: