Wood Pellet Production Expansion in Malaysia

Advanced wood chipping, milling, drying technology and stable equipment of SIMEC is helpful to process wooden materials accurately into proper size and moisture. Suitable size and mositure are helpful to produce high quality 8mm wood pellet. Featured with good transportability, moisture tolerance and high CV, the pellets are well received by the power plants.

All of the goods were delivered from Qingdao Port to Klang port, Malaysia on Oct. 11th, 2020. In total 6 pieces of 40’ HQ container and 2 pieces of 40’ FR container are stuffed for shipment.

Please find detail information of goods delivery at below:

Main Equipment:

Drum Dryer and ID Fan

|

Serial No.

|

No. |

Item |

Dimensions |

Weight |

Package Content |

|

1 |

SIMEC01 |

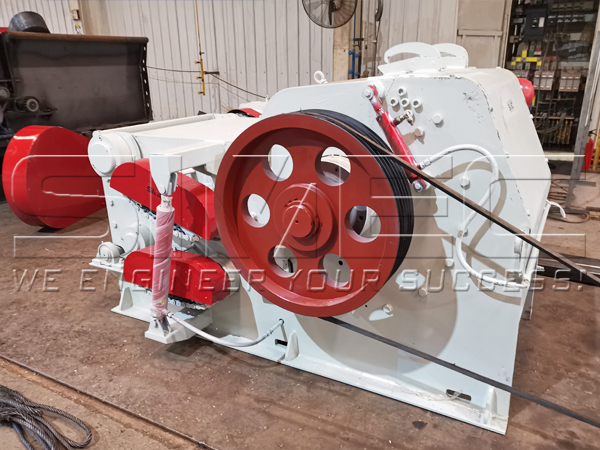

Chipper |

2500*2200*1500mm |

4811kg |

Chipper main body |

|

SIMEC02 |

2300*1000*1600mm |

320kg |

Feeding chute |

||

|

SIMEC03 |

1500*700*1000mm |

910kg |

Main driven motor |

||

|

SIMEC04 |

900*900*900mm |

540kg |

Belt, upper feed roller motor, lower feed roller motor, hydraulic station motor, 4 pieces of spare part chipping blades, tools |

||

|

SIMEC05 |

600*600*450mm |

30kg |

Hydraulic station |

||

|

SIMEC06 |

1972*840*250mm |

37kg |

Protection cover |

||

|

2 |

SIMEC07 |

Hot Air Stove |

6700*2560*2525mm |

20t |

Hot air stove main body, secondary blower |

|

SIMEC08 |

1010*1300*1300mm |

480kg |

Fire channel_section 2 (1 meter length) |

||

|

SIMEC09 |

4000*500*1100mm |

300kg |

Slag remover, hopper of slag remover |

||

|

SIMEC10 |

1530*1300*1300mm |

720kg |

Fire channel_section 1 (1 meter length) |

||

|

SIMEC11 |

1500*1000*900mm |

0.7t |

Fire grate motor and reducer; blower |

||

|

3 |

SIMEC12 |

Dryer |

11080*3300*3300mm |

35t |

Dryer main body |

|

SIMEC13 |

2800*2200*800mm |

2t |

Riding wheel seat |

||

|

SIMEC14 |

2800*2400*800mm |

2.5t |

Riding wheel seat with thrust wheel |

||

|

4 |

SIMEC15 |

Hammer Mill |

3200*2250*2350mm |

6020kg |

Hammer mill main body |

|

SIMEC16 |

6000*2250*2500mm |

2280kg |

Feeding hopper, setting bin, three way separator, base, air lock, butterfly valve, flue pipe of fan, flue pie of dust collector |

||

|

SIMEC17 |

8500*2250*2600mm |

5700kg |

Fan, fan base, dust collector(U-steel support), Discharge augers, 20 pieces of fabric tubes, chiller, single auger, dual auger, conveyor, dust collector(upper part),dust collector(lower part), standard parts in a box. |

||

|

5 |

SIMEC18 |

Dryer Auxiliary machine |

6500*2100*2100mm |

2684kg |

Circle auger, U-type auger, cyclone discharging auger, square to round joint, elbow, shell, rear and front closure heads, 5 pieces of belt conveyor, square bin |

|

SIMEC19 |

6000*2100*2000mm |

3133kg |

Triaxial auger, stock bin, 2 elbows, air lock, 2 pcs of belts, round straight pipe, hood cover, belt conveyor(nosing and tail) 2 pcs, 4 pcs of ground legs, triaxial auger discarging port |

||

|

SIMEC20 |

3700*2900*1500mm |

789kg |

Duplex 1200 cyclone |

||

|

SIMEC21 |

2500*1210*2470mm |

340kg |

Cyclone support |

||

|

SIMEC22 |

1300*1160*2080mm |

196kg |

Triaxial auger support |

||

|

SIMEC23 |

2100*1100*1740mm |

88kg |

Dryer rear closure head-lower part |

||

|

6 |

SIMEC24 |

Control Cabinet |

1100*750*2200mm |

350kg |

Control cabinet (chipper) |

|

SIMEC25 |

1100*750*2200mm |

400kg |

Control cabinet (hammer mill) |

||

|

SIMEC26 |

1100*750*2200mm |

380kg |

Control cabinet (dryer), thermocouple, diaphragm seal |

||

|

7 |

SIMEC27 |

ID Fan |

2500*1600*1500 |

2500kg |

Fan, air valve. |

|

8 |

SIMEC28 |

Spray Tower |

6000*1800*1800mm |

650kg |

Spray tower body |

|

SIMEC29 |

1500*1500*1500mm |

150kg |

14 pieces of flanges, 1 piece of rain cap, 1 piece of φ600 elbow, 1 piece of reducer, 1 piece of fuse machine, 2 pieces of small elbows, 1 piece of pipe, 2 pieces of water valve, 1 meter length of φ315 water pipe, 1 bag of self-drilling screw, 1 piece of glue gun, 3 pieces of glues |

||

|

SIMEC30 |

6000*1200*1200mm |

210kg |

4 pcs of pipes |

||

|

SIMEC31 |

1000*500*400*mm |

50kg |

Water pump |

Release date: 2020-12-07