Napier Grass Drying & Pelletizing System Delivery to Manila

Napier grass is also called bana grass, once the equipment of drying system and pelleting system is transported in place, client can start installation.

All the equipment will be sent from Qingdao to Manila in 5 set of 40’ GP container and 2 sets of 40’ frame container by ship.

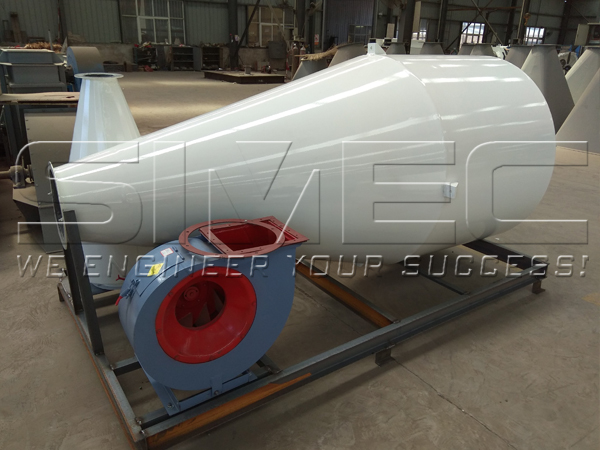

Photos of drying system and pelletizing system equipment:

The packing list of drying and pelletizing system equipment:

| Packing List Drying System | |||||

| No. | Main Item Name | Detail Equipment List | Amount | Dimensions-mm | Weight |

|

SIMEC① |

Barrel Body |

Shell cover support | 4 |

3220x3220x11000 |

35t |

| Fire passageway | 1 | ||||

| 180 degrees elbow | 1 | ||||

| 90 degrees elbow | 3 | ||||

| Pipes | 4 | ||||

| Reducer | 1 | ||||

| Cyclone dust collector support | 4 | ||||

| Cyclone dust collector stull | 4 | ||||

| Air blower | 1 | ||||

| Air blower reducer | 1 | ||||

| Fire grate reduction gear | 1 | ||||

| Upper supporting roller frame | 14 | ||||

| Belt conveyer support | 5 | ||||

| Belt conveyer flange | 5 | ||||

| Twill tape | 2 rolls | ||||

| Upper supporting roller | 28 | ||||

| Lower supporting roller | 5 | ||||

| Block roller | 8 | ||||

| Motor | 3 | ||||

|

SIMEC② |

Water Tank |

B type triangular belt 1850 | 5 |

1400x1400x2000 |

2.5t |

| Silicon steel sheet | 132 | ||||

| Temperature probe | 2 | ||||

| Bolt | 2 boxes | ||||

| Belt buckle + soft steel wire | 1 | ||||

| Frequency converter | 2 | ||||

| Acrylic + swallowtail wire | 1 | ||||

| Block leather | 28+3 | ||||

| Airlock valve | 1 | ||||

| Electric control cabinet | 1 | ||||

| Signal wire | 100m | ||||

| SIMEC③ | Front shell cover | Single | 1 | 2500x2000x700 | 0.35t |

| SIMEC④ | Rear shell cover | Single | 1 | 2500x2000x700 | 0.36t |

| SIMEC⑤ | Feeding belt conveyor | Single | 1 | 10200x900x600 | 0.5t |

| SIMEC⑥ | Hot air stove | Single | 1 | 6000x2500x2300 | 15t |

| SIMEC⑦ | Hot air stove feeder | Single | 1 | 6200x900x600 | 0.4t |

| SIMEC⑧ | Stock bin | Single | 1 | 1600x1600x1200 | 0.3t |

| SIMEC⑨ | Cyclone dust collector | Single | 1 | 1600x1600x1201 | 1t |

| SIMEC⑩ | Fire passageway | Single | 1 | 1600x1600x1202 | 1.2t |

| SIMEC⑪ | Feed screw conveyor | Single | 1 | 1600x1600x1203 | 0.8t |

| SIMEC⑫ | Residue output machine | Single | 1 | 1600x1600x1204 | 1t |

| SIMEC⑬ |

Output screw conveyor (half) |

Single | 1 | 1600x1600x1205 | 1t |

| SIMEC⑭ |

Output screw conveyor (half) |

Single | 1 | 1600x1600x1206 | 0.8t |

| SIMEC⑮ | Roller support | Single | 1 | 1600x1600x1207 | 2.5t |

| SIMEC⑯ | Block roller support | Single | 1 | 1600x1600x1208 | 2.8t |

| SIMEC⑰ | Draught fan | Single | 1 | 1600x1600x1209 | 2.5t |

| SIMEC⑱ | Air compressor | Single | 1 | 1600x1600x1210 | 0.1t |

| SIMEC⑲ | Straw cutter | Single | 1 | 1600x1600x1211 | 1t |

| SIMEC⑳ | Diesel engine | Single | 1 | 1600x1600x1212 | 0.15t |

| Packing List Pelletizing System | |||||

| No. | Device Name |

Amount (pcs) |

Weight (t) |

Length*Width*Height Unit:mm |

Remarks |

| 1 | 50/28 Bucket Elevator Head | 1 | 0.52 | 1720x1380x1210 | Including 1 500 air door |

| 2 | 40/23 Bucket Elevator Head | 1 | 0.50 | 1650x1200x1150 | Including 2 5L airlock valves |

| 3 | 50/28、40/23Bucket Elevator Head Tail(2 pieces) | 1 | 0.52 | 1500x1350x1720 | Including 2 25x40 valves |

| 4 | 25 Scraper Head & Tail(1 piece for each) | 1 | 0.33 | 1170x1110x1120 | |

| 5 | 25 Scraper Straight Pipe(4 pieces) | 1 | 0.35 | 2140x800x1110 | |

| 6 | 520 Pellet Mill Lower Part(including conditioner) | 1 | 6.20 | 2700x2200x2200 | |

| 7 | 520 Pellet Mill Lower Part(Including conditioner) | 1 | 6.20 | 2700x2200x2200 | |

| 8 | 520 Pellet Mill Lower Part(Including conditioner) | 1 | 6.20 | 2700x2200x2200 | |

| 9 | 520 Pellet Mill Widemouthed Feeder(2 pieces) | 1 | 0.74 | 1960x1560x1900 | |

| 10 | 520 Pellet Mill Widemouthed Feeder(1 piece) | 1 | 0.50 | 1960x1470x950 | Including 520 pellet mill accessories box (3 eccentric shaft adjustment tools, 3 hook wrenches, 3 ring die lifting hooks, 3 crow bar, 3 torque wrenches, 3φ30 pullovers, 3 sets of gauge stand and dial indicator, O type sealing ring(φ75、φ20),18 ring die disassembly bolts M20x80, 15 shear pins, 1 lubricator, 6 φ90 hose clamps,3 thermometers) |

| 11 | φ800 Cyclone | 1 | 0.33 | 1950x980x2070 | Including 1 4-72-11 draught fan, 2 flanges |

| 12 | φ1200 Cyclone | 1 | 0.43 | 2600x1400x1470 | Including 1 4-72-2.2 draught fan,1200 anti-block,2 flanges |

| 13 | 19x19 Cooler Upper Part | 1 | 1.10 | 2010x2010x2080 | Including 2 boxes of standard parts, 1 box of level meter (including cooler level meter),2 bundles of bucket belts,1 box of 40magnetic core,5 pieces of 25 scraper upper junction plate,5 pieces of lower junction plate, 10 pieces of side junction plate, 80 pieces(1 bag) of scraper blade,16mφ90 soft pipe,1 set of cooling screen, 1 piece of 40x4 sealing strip,1 piece of sealing strip 30x3 |

| 14 | 19x19 Cooler Lower Part | 1 | 1.70 | 2770x2180x1600 | Including 12 pieces of pelleting chamber board |

| 15 | 19x19 Cooling Screen | 1 | 0.56 | 2760x2190x1190 | |

| 16 | 19x19 Cooler Support | 1 | 1.14 | 2490x2170x1750 | Including 12 joints of 5028 bucket elevator straight pipe, 36 pieces of inside and outside stand of pelleting chamber and bottom sealing board in total, 2 bags of bucket bolt, 104 pieces of 5028 elevator bucket and 68 pieces of 4023 elevator bucket |

| 17 | Elevtric Control Cabinet(4 pieces) | 1 | 1.12 | 2190x1590x2200 | |

| 18 | Elevtric Control Cabinet(1 piece) | 1 | 0.43 | 1150x830x2200 | |

| 19 | 40/23Bucket Elevator Straight Pipe | 1 | 0.34 | 2060x800x2060 | 10 joints |

| 20 | 40 Permanent Magnet Barrel Feed Hopper | 1 | 0.06 | 900x900x720 | |

| 21 | 40 Type Permanent Magnet Barrel | 1 | 0.31 | 1250x900x1010 | Including 1 16L airlock valve |

| 22 | LSS40 Screw Conveyor | 1 | 0.45 | 4000x520x690 | |

| 23 | 40 Screw Conveyor Output Hopper | 1 | 0.03 | 800x520x660 | |

| 24 | Bucket Hopper | 1 | 0.62 | 1490x1490x1120 | Including 19 joints of 25 scraper chain, 78 flanges, elbow pipes, feed hoppers, outlets and other carbon steel non-standard parts |

| 25 | Bucket Hopper | 1 | 0.15 | 1490x1490x1000 | |

| 26 | Bucket Hopper | 1 | 0.15 | 1490x1490x1000 | |

| 27 | 16L Airlock Valve Feed Hopper | 1 | 0.04 | 900x900x520 | |

| 28 | 4023 Bucket Elevator Feed Hopper | 1 | 0.04 | 880x780x720 | |

| 29 | Flow Pipe | 1 | 0.35 | 6050x450x520 | Copper Bars |

| 30 | Stainless Steel Plate Chain | 1 | 0.50 | 2650x950x740 | |

| Total | 31.91 | ||||

Release date: 2017-07-03