Cotton Stalk Pellet Plant Delivery to Uzbekistan

SIMEC is now strategic partner of the biggest producer of pellet burners and pellet boilers in Central Asia. As supplier of pelletizing technology & pellet machines, SIMEC will build a complete cotton stalk pellet project in Uzbekistan. Capacity is designed to be 2 tons/hour, including two sets of SPM420 biomass pellet mills.

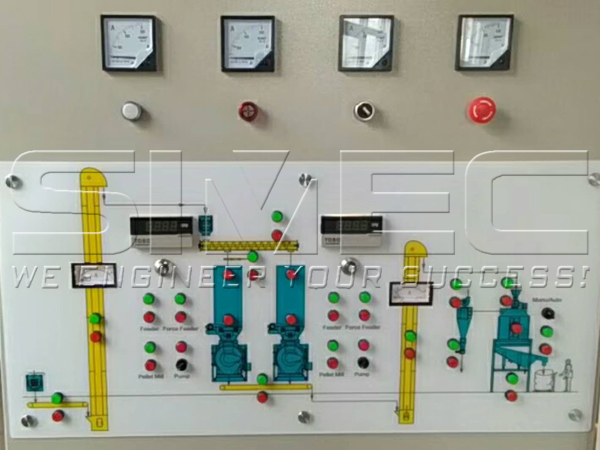

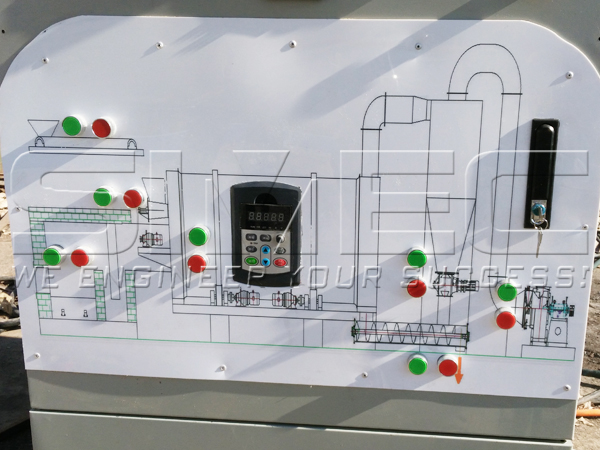

The pellet project consists of cotton stalk crushing system, drying system, pelletizing system, pellet cooling & sieving system, jumbo bag bagging system, electric control system, etc..All machines are fabricated in SIMEC mills and are ready for delivery. All cargos will be delivered to Tashkent by train. Totally 4 pieces of 40 ft containers are required to load all of these machines.

After Chinese New Year, SIMEC will send engineers to Tashkent and work on installation & commissioning. After successful running of this project, another 4 tons/hour complete cotton stalk pellet plant will be built accordingly.

Overall Dimension of SPM420 cotton stalk pellet mill: Length 2800mm x Width 1250mm x Height 2200mm. Gross weight: 3.2 Tons.

Packing details of pelletizing system:

| No. | Item | Qty. | Weight(t) | LxWxH:mm | Remarks |

| 1 | Cooler lower part | 1 | 1.290 | 2370x1650x1700 | Including reduction box, vibration motor, 8 pieces of asseble bin plates. |

| 2 | Cooler upper part | 1 | 0.540 | 1550x1500x1700 | galvanized iron air screens, elevator bolts,1 bag of tape splicing block, 1 box of 25 magnetic core, 3 boxes of standard components(icluding 2 pcs of upper feed levelers, 2 pcs of lower feed levelers, 1 pc of screw feed leveler cooler, sealing strip, 2 sets of leveler bases, 2 electromagnetic switch). |

| 3 | Head and tail of elevator | 2 | 0.834 | 1550x1500x1800 | 1 set of 9L airlock valve,2 sets of 2.2-3-17 reducers for elevator, 2 motor frame, 1 set of 25 permanent magnet barrel. |

| 4 | Cone bucket 1 | 1 | 0.400 | 1530x1530x1230 | 9 pcs of non-standard pipe bending, 36 pcs ofΦ400 flange |

| 5 | Cone bucket 2 | 1 | 0.504 | 1530x1530x1230 | 2 rolls of fix belt, 1 pcs of 20A chain, 3 bags of bucket elevator, 2 rolls of elevator belt, 6 flat rollers, 18 short rollers, 18 side supporters, 8 lower supporters, 4 parallel supporters and 1 protection shell. |

| 6 | LSS25 Auger | 1 | 0.304 | 4500x460x580 | Including reducer |

| 7 | Elevator straight pipe | 1 | 0.908 | 2040x1950x1700 | 1 cooler supporter, 14 pcs of 2M straight pipe, 4 pcs of connections, 3 kinds of assemble chamer supporter 24 pcs. |

| 8 | Φ1000 cyclone | 1 | 0.590 | 2500x1230x1320 | 1 set of 5 L air lock valve, 1.5-3-29、2.2-3-17 fixed reducer,4-72-4.5A-7.5K air blower, 1 set of W1,2 pcs of Φ219 pipe |

| 9 | 50 stationary type | 2 | 0.520 | 5000x850x1550 | 2 material trouwing shells, 3 feeding hoppes, 2 motor supporters, 1 pc of 25X40 pneumatic gate valve |

| 10 | Electric cabinet | 1 | 0.362 | 1180x850x2050 | |

| Total | 6.252 |

| No. | Item | Size (MM) | Weight(kg) |

| 1 | Motor | 2800*1700*2050 | 3155 |

| 2 | Bending pipe | 325*1200 | 26 |

| 3 | Striaght pipe | 325*4540 | 74 |

| 4 | Bending pipe | 325*900 | 22 |

| 5 | Cyclone | 4600*2200 | 402 |

| 6 | Cyclone ground legs(2 pcs) | 3800*1570 | 124 |

| 7 | Cyclone crossgirder | 1430*180 | 28 |

| 8 | Double bending pipe | 273*2250 | 38 |

| 9 | Striaght pipe | 273*5120 | 70 |

| 10 | Bending pipe | 273*950 | 16 |

| 11 | Draught fan including motor | 1200*1050*1000 | 314 |

| 12 | Striaght pipe | 273*2900 | 42 |

| 13 | Bending pipe | 273*960 | 18 |

| 14 | Dust collector ground leg | 4500*150 | 74 |

| 15 | Upper dust collector box | 2150*2000 | 160 |

| 16 | Lower dust collector box | 2000*1950*1100 | 170 |

| 17 | Dust collector door | 2250*960 | 74 |

| 18 | Dust collector back plate | 2500*1900 | 172 |

| 19 | Conveyor supporter | 6000*1030 | 124 |

| 20 | Conveyor ground leg | 1800*2030 | 22 |

| 21 | Conveyor roller | 900*320 | 10 |

| 22 | Conveyor roller | 380*320*300 | 30 |

| 23 | Conveyor front roller | 1100*270 | 60 |

| 24 | Conveyor rear roller | 1120*270 | 56 |

| 25 | Conveyor roller supporter | 1000*400 | 18 |

| 26 | Conveyor reducer including motor | 70*350 | 90 |

| 27 | Cyclone accessories | 300*300 | 20 |

| 28 | Conveyor motor supporter | 1000*570*510 | 34 |

| 29 | Belt | 800*450 | 94 |

| 30 | Switch box | 1750*720*410 | 85 |

| 31 | Screw, cloth bag | 600*300 | 28 |

| 32 | Air lock valve, reducer, motor | 1000*400*410 | 140 |

| 33 | Air lock valve discharging pipe | 325*500 | 6 |

| Total (33pcs) | 5796(kg) |

| No. | Item | Equipment | Qty. | Size(L*W*H) | Weight(KG) |

| SIMEC-1 | Main Body | 1 | 11900*2330*2480 | 12950 | |

| SIMEC-2 | Hot air stove | 1 | 3200*2360*2130 | 9504 | |

| SIMEC-3 | Cyclonedust collector | 1 | Φ1600*4200 | 421 | |

| SIMEC-4 | Electric control cabinet | 1 | 1000*800*450 | 82 | |

| SIMEC-5 | Induced draft fan | 1 | 1900*1000*1000 | 280 | |

| SIMEC-6 | Belt conveyor | Ground legs | 1 | 8000*600*500 | 585 |

| SIMEC-7 | Discharging machine | 1 | Φ219*3800 | 280 | |

| SIMEC-8 | Water tank | Whole set screw | 1 | Φ1200*1500 | 312 |

| SIMEC-9 | Air blower | 1 | 500*500*400 | 55 | |

| SIMEC-10 | Large U-type elbow | 1 | 1800*Φ400*700 | 105 | |

| SIMEC-11 | Small U-type elbow | 1 | 1600*Φ400*700 | 95.6 | |

| SIMEC-12 | Long elbow | 1 | 1200*Φ400*700 | 74.7 | |

| SIMEC-13 | Short elbow | 1 | 700*Φ400*700 | 56.8 | |

| SIMEC-14 | Long reducing elbow | 1 | Φ400-850 | 34 | |

| SIMEC-15 | Short reducing elbow | 1 | Φ400-360 | 19.5 | |

| SIMEC-16 | Air blower inlet port reducing elbow | 1 | Φ600-Φ400*350 | 44 | |

| SIMEC-17 | Connection pipe | 1 | Φ400*2840 | 89.7 | |

| SIMEC-18 | Chimney | 1 | Φ400*3000 | 93.9 | |

| SIMEC-19 | Hopper | 1 | 1300*1300*1000 | 112 | |

| SIMEC-20 | Air lock valev | 1 | 800*400*400 | 54.3 | |

| SIMEC-21 | Weight Scale | 1 | 1200*1200*300 | 125 |