Biomass Pyrolysis Research Equipment Delivery to Egypt

With the help of SIMEC technology, the Egyptian laboratory is well equipped to do all the biomass pyrolysis experiments. Please read the following introduction to know more about the shipping list.

1. Size reduction equipment, such as biomass milling, grinding and shredding machines.

2. Biomass leaching apparatus.

Leaching technology is used to reduce the content of ash and K, Na, S, Cl, etc. It’s helpful to improve combustion performance of biomass fuel.

Besides leaching function, the customized leaching apparatus is equipped with pH value monitoring module, solvent heating module. Temperature & pH value of the solvent can be adjusted and real-time monitored according to experiment requirement.

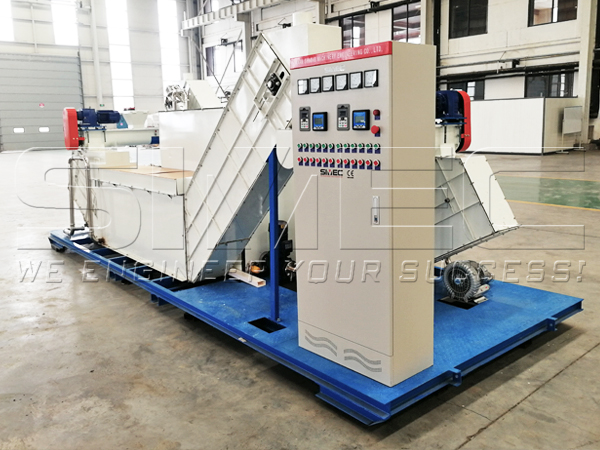

3. Dryer and screw dewatering press.

4. Biomass pyrolysis apparatus.

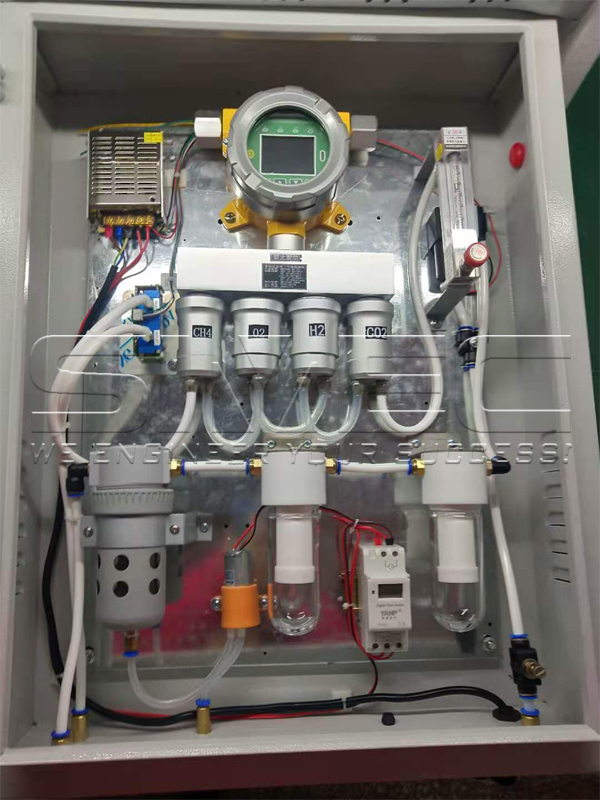

Pyrolysis a thermochemical process in an inert or limited oxygen environment, where biomass is slowly heated to within a specified temperature range and retained there for a stipulated time for conversion of an organic substance into carbon or a carbon-containing residue. The major objective is to increase the energy density of the biomass by increasing its carbon content while decreasing its oxygen and hydrogen content. The pyrolysis apparatus is equipped with syngas detecting and monitoring module. The content ,ratio and calorific value of pyrolysis gases can be detected and analyzed by the module instantly.

5. Pellet mill for laboratory use. Pelleting will increase the energy density of biomass.

6. Pellet cooling and sieving equipment.

Main Equipment:

Laboratory Hammer Mill, Chipping and Milling Machine

Biomass Leaching Apparatus

Synthesis Gas Detecting & Monitoring Module, Pellet Mill

The goods were shipped to Alexander port, Egypt on Jan. 6th, 2021. In total 2 pieces of 40’ HQ containers were loaded. Container Loading No. 1 & 2:

Packing Details:

| No. | Packing Dimensions | Gross Weight | Packing Details |

| SIMEC01 |

4000*2200*2050 mm |

2074 kg |

One unit of biomass laboratory pyrolysis apparatus, feeding auger, hammer mill, shredder, air compressor. Total Weight:1916kg L*W*H:4000*2200*2050mm Below is packing data of each main items: Hammer mill including spare sieves. Weight: 72kg. L*W*H:620x490x570mm. Grass Shredder Weight: 66kg. L*W*H:1100x500x800mm Air compressor Weight:20kg. L*W*H:590x320x520mm |

| SIMEC02 |

1480*690*685 mm |

80 kg |

Accessories of pellet cooler: Cooling fan, dust collector, 3 pcs of flexible tube. |

| SIMEC03 |

4200*1190*1140 mm |

420 kg |

Cooling conveyor |

| SIMEC04 |

600*1000*1600 mm |

180 kg |

Mixing tank and its control cabinet |

| SIMEC05 |

5800*2200*2200 mm |

2500 kg |

Biomass leaching laboratory apparatus |

| SIMEC06 |

700*800*830 mm |

112 kg |

Pellet sieve |

| SIMEC07 |

500*850*1900 mm |

140 kg |

Control cabinet, laptop and accessories. |

| SIMEC08 |

520*380*490 mm |

8 kg |

Handheld moisture meter, halogen moisture meter |

| SIMEC09 |

1450*700*850 mm |

310 kg |

Chipping & Milling laboratory apparatus |

| SIMEC10 |

1490*1080*670 mm |

116.3 kg |

Laboratory drying apparatus |

| SIMEC11 |

640*470*180 mm |

15.6 kg |

Syngas online monitoring and analysis module |

| SIMEC12 |

2000*750*900 mm |

265 kg |

Feeding screw conveyor |

| SIMEC13 |

2000*700*1150 mm |

200 kg |

Screw dewatering press |

| SIMEC14 |

2800*1350*1550 mm |

200 kg |

Mixing machine, corner rising legs |

| SIMEC15 |

4200*500*450 mm |

100 kg |

Elevating auger and pumping conveyor |

| SIMEC16 |

1300*1200*1450 mm |

500 kg |

SPM250 pellet mill |

| SIMEC17 |

1000*800*950 mm |

50 kg |

Buffer bin, flexible tubs |

| SIMEC18 |

800*700*450 mm |

150 kg |

Spare parts of SPM250 pellet mill: Ring die, roller shell and roller assemb |