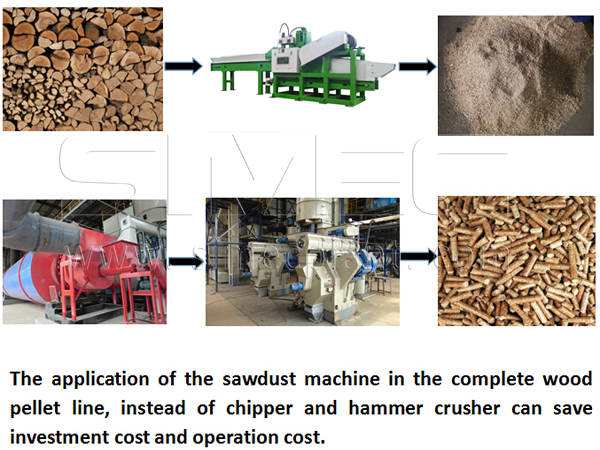

From Wood Log To Pellet Without Chipper and Hammer Crusher

SMX sawdust machine is going to be popular in the wood pellet manufacturing market, because of its simple size-reducing to convert the wood logs, long wood chips, wood branches and other big size wood raw materials to sawdust directly. Normally, wood logs as the raw material in one set of wood pellet line, the chipping system, hammer crushing system and dryer will be needed to reduce the size of the wood log into 3-5 mm suitable for the wood pelleting system. But now, the chipping system and crushing system can be combined into one-stop sawdust making system. Thanks to the application of the SMX sawdust machine, comparing with the normal size reducing pre-treatment, the whole wood pellet manufacturing procedure is compacted to sawdust making, drying pelleting, cooling&sifting, and packing system. Not only does the sawdust machine save the labor and power consumption cost, but the quality of the raw materials can be further guaranteed.

With application with the hydraulic feeding system and high strength knives made from tungsten steel, the sawdust machine can process wood logs, long wood chips, wood branches with diameter under 350 mm into 3-5 mm sawdust efficiently and stably. Unlike other size reduce equipment, it is easy to be maintained during the regular operation. What can be done to the machine is just to add indicated hydraulic oil as the meter showing, and repair the knives every 4-6 months according to the practical performance.

Please do not hesitate to send inquiry to us, if you are interested to the complete wood pellet line proposal with one-stop sawdust making machine.

SMX Sawdust Machine