Multi Function Solid Waste Shredder

SIMEC series Double Shaft Shredder, use CE motor certificated by EU.SIMEC double shaft shredder adopt the automatic system controlled by microcomputer (PC). The control system is adopted with start, stop, reversal and overload automatic reversal control functions with the features of lows peed rotation, large torque and low noise, etc. The bearing seat adopts the open type, which is easy and convenient to dismantle and change the door, suitable to shred the large, thick and strong materials.

Materials that can be shredded by this shredder are as followings:

1, Various hollow container: plastic beverage cans, plastic barrels, drums, packing box and packing barrel, etc.

2, Waste electrical appliances: TV set, washing machine and refrigerator shell, etc.

3, Pipe: large pipes, pipe fittings and PE pipe, etc.

4, Waste template: wooden pallets, plastic pallets and forklift pallet, etc.

5, Waste tires: car tires, truck tires, etc.

6, Scrap metal: car shell, aluminum, scrap aluminum casting, engine casing, lead and steel in thickness of 5mm or less.

7, The restaurant kitchen garbage, household waste, animal carcasses, RDF derivatives, medical waste, biological straw and garden waste, etc.

8, Plastic head material, paper plant twisted rope.

Important Notes:

1, Shredder blade thickness is divided into 15mm, 20mm, 40mm, 50mm, 75mm and 100mm, the knife blade can be chosen according to the pellet size needed after shredding.

2, The Shredder knife blade is a single claw one, if users need double claw blade or multi claw blade, please contact with the business department.

3, The thickness and the number of claw knife of Shaft Shredder can be replaced according to different materials. It can be equipped with pressing device in order to improve the production while crushing hollow materials,

Structure Features:

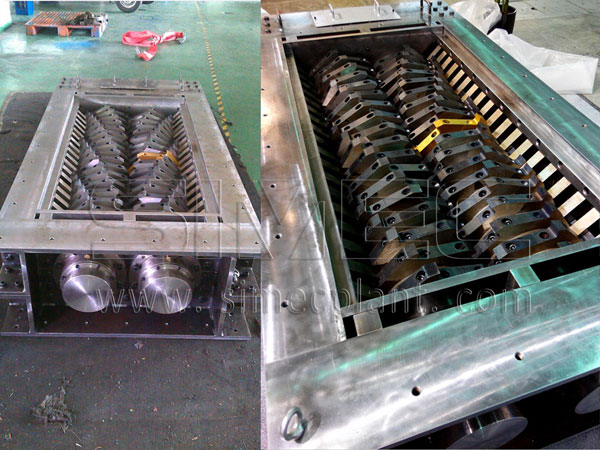

1.Shredder Body

The main body of the device is made of high quality steel plate welded to eliminate stress treatment/ modular machining, to ensure the stability of equipment in the heavy load for a long time.

2. Rolling Crushing Knife/ Fixed Knife

Rolling crushing knife material adopts special alloy tool steel forging blank, precision machining, repeatedly heat treatment and cryogenic freezing heat treatment technology. the overall hardness and toughness keeps the same and can repeatedly repair, ensuring the cutting capability and service lifetime. Fixed knife uses patent hook type installation, enhanced the function of changing knifes, making them more efficient to maintain and change.

3,Shaft/Seal

The shaft seat adopts patent split detachable type, components such as the rolling crushing knife, fixed knife and bearing can be quickly removed, making knifes easy to maintain and change. Special seal structure can efficiently stop the touch between broken materials and grease, and can also protect the shaft and gear wheel when dealing with liquid materials.

4.Knife Bearing

Refined by special high-strength overloaded steel, coordinate knifes and provide more energy for cuttings more reasonable.

Performance Characteristics

1, This machine can shred large pieces of hard flour mill feed, basket materials, pipe, sheet metal, wood, tires, scrap metal drums and large roll film that general machine cannot break.

2,Special thick sheet precision machining composite structure frame, powerful wide-angle hexagonal columns rotating shaft and large diameter solid Input hopper, making it safely for you to input raw materials.

4,Low knife shaft speed, low noise and less dust.

5,The tool produced by special alloy steel, durable.

Solid Waste Shredder

Wood Shredder SD1000

Wood Shredder SD1500

Blade Details

Blades Sideview

Mainbody Blades Double Shaft

Shredded Wood Template