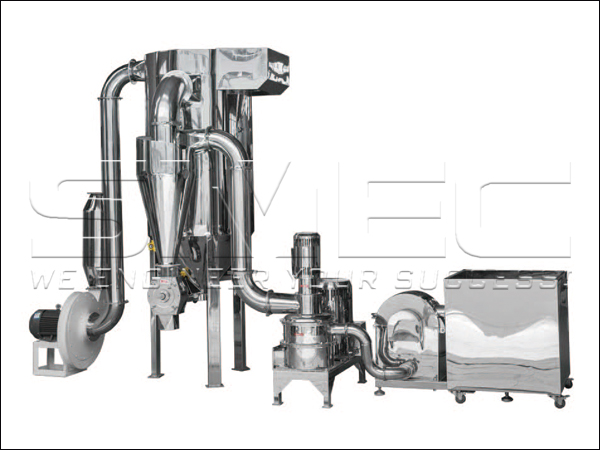

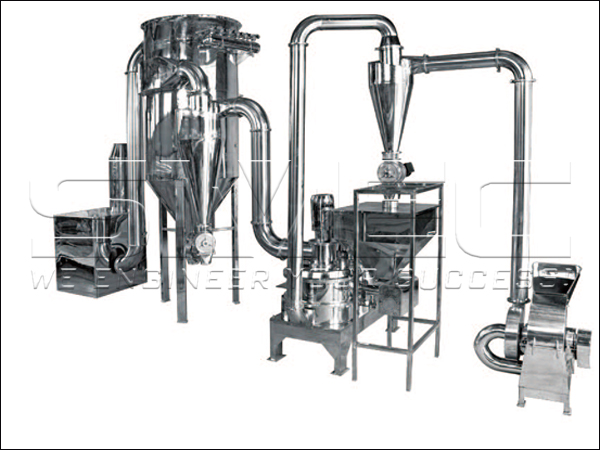

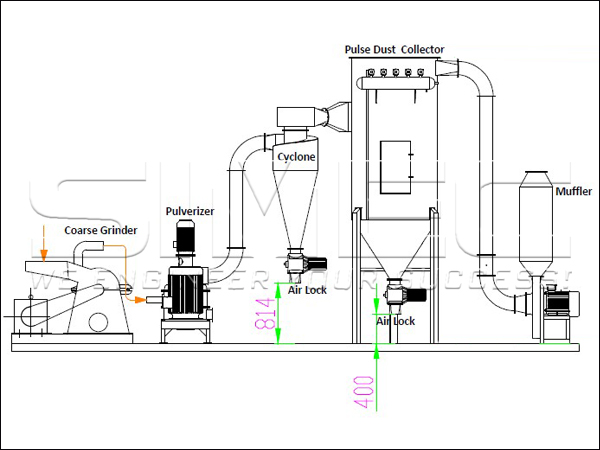

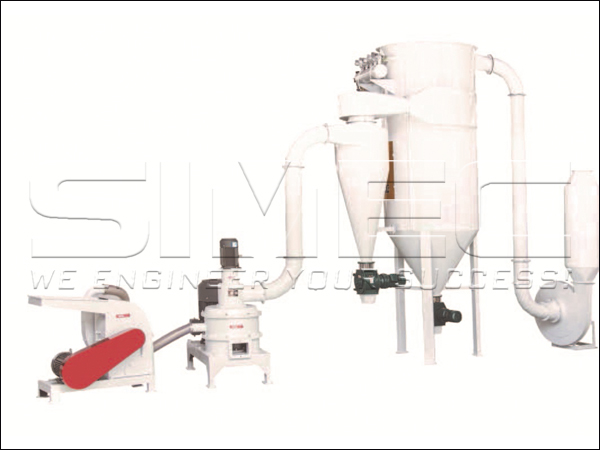

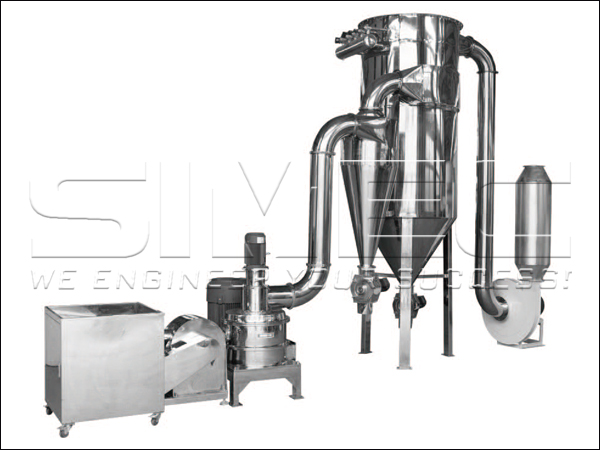

Integrated Coarse Grinding and Fine Pulverizing

Working Principle:

Material is fed into the coarse grinder through the hopper. After grinding, the material is sucked into the cavity of the ultra-fine pulverizer under the negative pressure condition. The qualified pulverized product is sucked into the cyclone and discharged through the air lock. The larger particles are thrown out and dropped down to the pulverizing rotor to be pulverized again. The fine dust is sucked into pulse dust collector, and collected from the air lock. The clean air is discharged from the exhaust outlet of the fan.

The pulverizing system performs under the condition of closed negative pressure, dust-free production can be achieved. The negative pressure air flow can continuously take away the heat generated in the pulverizing chamber during production, greatly reducing the temperature of the equipment and materials.

Features:

Technical Parameters:

All models in the above table can be made of stainless steel or carbon steel, according to the usages of the powder products. Stainless steel models are often used in food, medicine, aquatic feed and chemical processing. The carbon steel models are used to pulverize biomass and carbon materials.- Coarse grinding and fine pulverizing all in one, multi size raw materials can be processed.

- Screen free structure design for the pulverizer, free of blockage;

- Pulverizing process is highly efficient controlled, low energy consumption.

- Innovative design of pulverizing mechanism, high yield, uniform fineness and low temperature rise on material;

- Rugged transmission technology, steady operation;

- 60 to 1000 mesh can be adjusted dynamically without shutting down the pulverizing machine;

- Interlock controlling system and overloading protection system, ensuring operation safety;

- Multi stage powder unloading system is composed of cyclone separator and pulse dust collector, enhancing production yield and no dust spilling over.

| Model | CGFP30 | CGFP40 | CGFP50 | CGFP75 |

| Grinding Disc Diameter (mm) | 300 | 400 | 500 | 750 |

| Fineness (mesh) | 60-1000 | 60-1000 | 60-1000 | 60-1000 |

| Main Motor (kW) | 18.5 | 30 | 45 | 75 |

| Grading Motor (kW) | 1.5 | 3 | 3 | 4 |

| Air Lock (kW) | 0.75*2 | 0.75*2 | 0.75*2 | 0.75*2 |

| Coarse Grinder (kW) | 7.5 | 11 | 11 | 22 |

Spices Raw Material

Woody Biomass

Wood Charcoal

Knives: The knives are made of high-strength alloy steel, hard and durable. The knives can be tailored as per specific project conditions. The weight of each knife is the same, ensuring dynamic balance and stable operation;

Gear Ring: Made of casting alloy steel and through CNC machining, the gears are inserted with wear-resisting alloy steel, enhancing wear resistance and prolong service life;

Grading Impeller: Driven by frequency conversion motor, according to tailored design, the impeller is precisely manufactured upon the specific fineness requirements.

.jpg)

Knives

.jpg)

Gear Ring

.jpg)

Grading Impeller

Please do not hesitate to contact us by info@simecpellet.com if you have any inquiry.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.