Guidelines for Clean and Safe Biochar

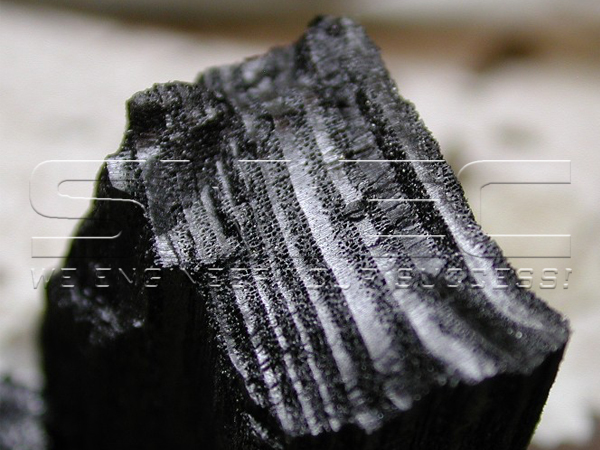

Good biochar has high percentage of stable (non-volatile) carbon, high porosity, extensive microstructure, high cation exchange capacity and adsorption capacity that enable beneficial interactions between microbes, nutrients, and water in the soil. However, some biochar may also contain contaminants that, when such biochar is applied to soil, can adversely affect soil flora and fauna.

From the perspective of SIMEC, pyrolysis unit design is the most important factor to produce clean and safe biochar, neither a specific pyrolysis parameter nor the feedstock. Good biochar shouldn’t be associated with a particular feedstock type.

The pyrolysis of organic materials causes the formation of polycyclic aromatic hydrocarbons (PAH). During biochar production, PAHs are usually released with the pyrolysis gases and are destroyed when these pyrolysis gases are combusted to produce thermal and electric energy. However, depending on the process conditions, a smaller or larger part of the released PAHs can be adsorbed by the simultaneously produced biochar.

The content of polycyclic aromatic hydrocarbons (PAHs) in biochar is very important factor to define the biochar’s application classes (Feed, Agro Organic, Agro, Urban, Consumer Material, Basic Material).

Limit values for PAH contents according to European Biochar Certification

| Certification Class | 16 EPA PAHs | 8 EFSA PAH |

| EBC-Feed | 4 mg/kg | 1.0 g t-1 DM |

| EBC-AgroOrganic | 4 mg/kg | |

| EBC-Agro | 6 mg/kg | |

| EBC-Urban | declaration | |

| EBC-ConsumerMaterials | declaration | |

| EBC-BasicMaterials | 30 mg/kg | 4 g t-1 DM |

According to the latest research, among the 16 US EPA PAHs, naphthalene (NAP) is the compound with the highest content, but the only one with two aromatic rings and the least toxic one. Thus, it is not considered to be carcinogenic nor genotoxic. Furthermore, NAP is also the most volatile PAH (vapor pressure 0.087 mm Hg at 25 °C) and evaporates significantly when present in soil. So, comparing with other parameters, the content of non-NAP PAHs is more important and more actual to define the class of a clean and safe biochar. According to test report issued by a third party lab., biochar made by SIMEC technology presents only 1.4 mg/kg non-NAP PAHs content, and 2.5 mg/kg 16 EPA PAHs content which is much lower than EBC standards.

It’s proved that appropriate production technology with advanced pyrolysis reactors and correct process control can avoid undesired PAH-contamination of biochar. The type of biomass feedstock used for biochar production has a negligible influence on the PAH content. Accordingly, a professionally designed pyrolysis reactor with advanced process control is the most important factor to produce clean and safe biochar.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.