Gearbox Transmission Pellet Mill

SPM series high-grade pellet mill is the main item of equipment for producing wood pellet with application to large and medium scale wood pellet plant.

The machine features compact structure, fine appearance, low noise, high output with low power consumption, it is convenient in operation and reliable in performance.

It can be fitted with dies of Ø6~Ø10 hole diameter, which can be chosen by user according to requirements.

The machine adopts (electromagnetic) frequency conversion speed-adjusting motor for feeder and LLL large door conditioner access, with moisture adding device.

Feeder is fitted with strong magnetic safety device, press overload protection device and external discharging mechanism.

SPM350 Pelle Mill

Main Body of SPM420

PRODUCT FEATURES:

1. High efficient one step gear driving ensures 98% utilization ratio of energy.

2. Full stainless steel feeder; variable-pitch anti-arch structure;imported frequency converter control.

3. Strong stainless steel conditioner extends the conditioning and cooking time. Comprehensive steam spraying port, improving feed cooking efficiency.

4. High precision of driving main gear and pinion shaft adopt the carbonizing quenching and hard tooth surface polishing technology, resulting in smooth driving, low noise and long service life. It comes from the guarantee of technology and experience of specialized gear factory and Germany numerical control equipment.

5. Material of gear box and high precision of driving holes also come from the guarantee of casting technology an experience of specialized casting factory and advanced numerical control equipment.

6. Main driving systerm uses high quality bearing and advanced numerical control equipment.

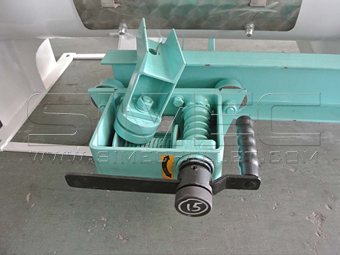

7. Quick removing type casting die clamp is adopted to connect the die and quill flange, resulting in convenient and quick removing of die.

8. Pellet chamber door and feed chute are fully made of stainless steel with two-cutting knife assembly,resulting in high anti-corrosion ability and long service life.

9. The connection between motor and gearbox adopts serpentine spring coupling with strong compensated displacement, which are more convenient to disassembling and assemble.

SPM350 Pelletizer for South African Project

SPM350 Pelletizer Installed

Auto-lubrication SPM420

Panited Screw Conveyor Conditioner SPM420

Rind Die Lift

Ring Die Lift SPM420

Ring Die SPM420

Screw Conveyor Conditioner Backside View

Screw Conveyor Conditioner Frontside View

SPM420 Pelletizer Malaysia

SPM420 Pellet Project Vietnam

Pellets produced by SPM420 pelletizer

Sample Video of Biomass Pellet Project: