Advantages of SIMEC Technology to Make Palm EFB Pellets

SIMEC has been specialized in complete biomass pellet projects since 1990. Now SIMEC produces more than 50 kinds of machinery related to the biomass pellet plant.

Currently the company has 120 active staff, in which 5 senior engineers, 30 engineers and technicians are included. Rich technical strength ensures our abilities to guarantee the product quality and comprehensive technical services.

We have set up more than 480 biomass pellet projects all over the world. 30 of the projects are in Indonesia.

SIMEC has been in the R&D to improve the value of palm EFB for many years. One of our most reliable solutions is to make palm EFB pellets. We have rich experience in making EFB pellets in Malaysia since years ago, and we know very clearly about how the EFB is generated from the palm oil mills and how to convert the EFB into pellets efficiently.

All of the equipment in the EFB pellet lines are researched by our engineers according to the nature of the raw materials.

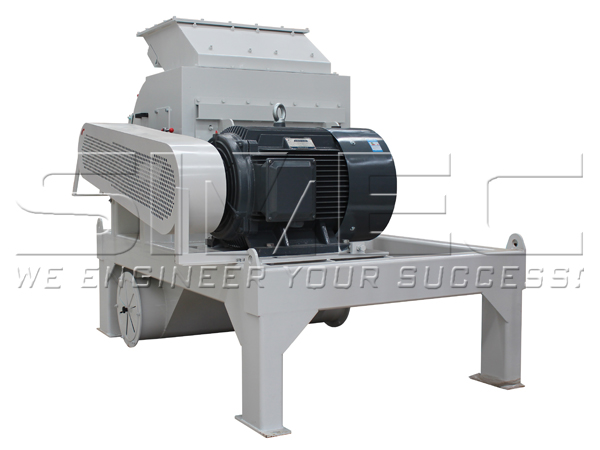

EFB Chopping Machine

As a fiber raw material with high oil and humidity content, it is not easy to reduce the particle size of the whole EFB. SIMEC EFB chopping machine can chop the whole EFB efficiently into 2-3 cm short fiber, which can be dried and crushed in the following steps easily.

Please check the video of the running EFB chopping machine for your reference.

http://www.simecpellet.com/product/palm_efb_machines/Palm_EFB_Chopping_Machine.html

Palm EFB Processing Site

EFB Fiber Rotary Dryer

Although the whole EFB is chopped into short fiber by the chopping machine, the fiber would be blocked easily inside the rotary dryer. So we improved the feeding system, inside structure of the drum and output discharge system to prevent the blockage of the fiber and make sure the EFB fiber will flow smoothly and guarantee drying efficiency.

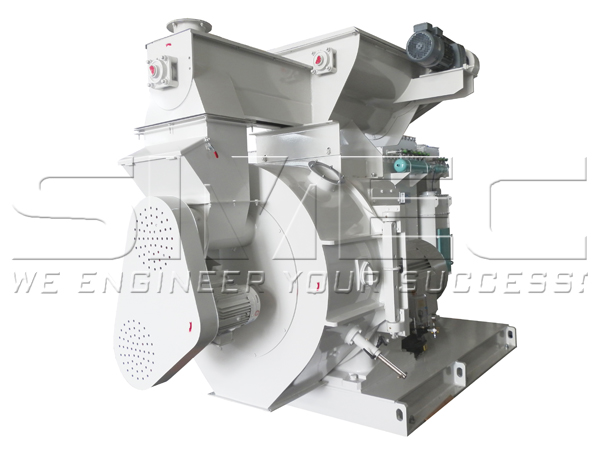

EFB Fiber Crusher

The EFB fiber crusher can crush the dried EFB fiber into small shorter fiber, which is suitable for the pelletizing. For processing the EFB fiber efficiently, we improved the hammers and screen. The head-saw hammers increase the crushing efficiency to the EFB fiber. The whole screen is separated into several individual parts; the customer do not need to change the whole screen, instead of just changing the individual wearing part.

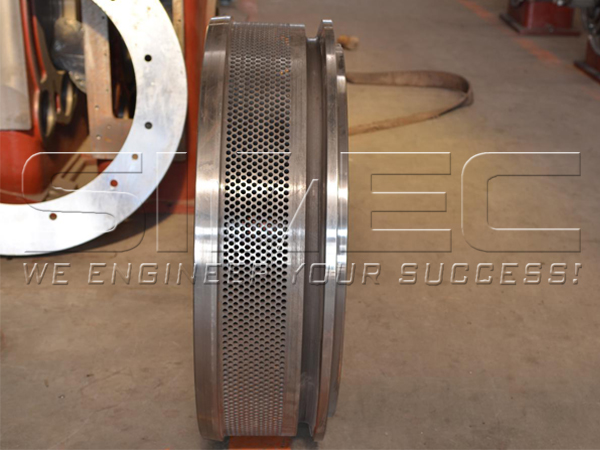

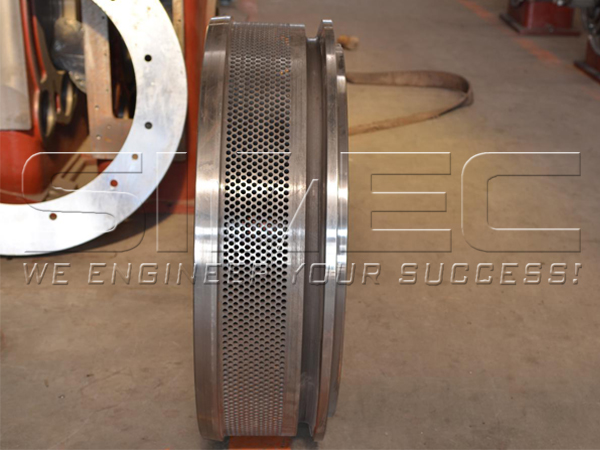

Hammer Crusher Knives

Screen of Hammer Crusher

EFB Fiber Pellet Mill

Like the pretreatment of the EFB, we redesign feeding system of the pellet mill to prevent the blockage of the raw material. We know that the material blockage will damage the feeding system and influence the normal running of pellet mill.

With years of experience, we know the best compression ratio of the ring die, which is the key point to produce good quality EFB pellets. The ring die is made of specific high strength alloy stainless steel and through the carburization heat treatment to increase the hardness and wearability, which guarantees the durability.

The transmission gears through the heat treatment are imported from Germany, the main shaft and hollow shaft is made of high quality forging part, CNC high precision machining, which makes sure the stable operation.

The pellet mill is also equipped with automatic lubrication system to the main shaft and the bearings of the rollers, which improves the working efficiency and save labors. SPM780 pellet mill is also equipped with automatic oil cooling and lubrication system to the transmission gearbox.

Thanks to the optimized transmission structure, our SPM780 pellet mill can produce 2.5-3 TPH EFB pellets with around 150 KWH/Hour power consumption.

The auto adjustable feeding system and the operation security system makes sure the safety of the operators.

SPM780 Automatic Lubrication Sytem

Automated Grease Lubrication Sytem

Ring Die of SPM780 Pellet Mill

Roller of SPM780 Pellet Mill

EFB Pellet Cooling & Sifting System

The counter-flow cooler can reduce the temperature of the EFB pellets efficiently and fast, which makes the packed pellets harder and drier. The rotary sifter can sift the unformed stuff from the final pellet product efficiently.

After-sales Services

SIMEC has a complete after-sales service system to provide fast and professional assistance and make sure pellet plant in good running condition. We have the most professional technician teams to help our clients complete the installation and commissioning of the EFB pellet project. After that, our technician can stay on site to train our clients’ technicians for several months according to clients’ requirements.

Marketing Assistance

Besides providing technology & equipment to the investors who want to convert palm EFB into palm EFB pellets, SIMEC can also introduce the market of EFB pellets to the investors.

We are sincerely committed to providing our clients with the most appropriate proposal, reliable equipment and acceptable services.

Currently the company has 120 active staff, in which 5 senior engineers, 30 engineers and technicians are included. Rich technical strength ensures our abilities to guarantee the product quality and comprehensive technical services.

We have set up more than 480 biomass pellet projects all over the world. 30 of the projects are in Indonesia.

SIMEC has been in the R&D to improve the value of palm EFB for many years. One of our most reliable solutions is to make palm EFB pellets. We have rich experience in making EFB pellets in Malaysia since years ago, and we know very clearly about how the EFB is generated from the palm oil mills and how to convert the EFB into pellets efficiently.

All of the equipment in the EFB pellet lines are researched by our engineers according to the nature of the raw materials.

EFB Chopping Machine

As a fiber raw material with high oil and humidity content, it is not easy to reduce the particle size of the whole EFB. SIMEC EFB chopping machine can chop the whole EFB efficiently into 2-3 cm short fiber, which can be dried and crushed in the following steps easily.

Please check the video of the running EFB chopping machine for your reference.

http://www.simecpellet.com/product/palm_efb_machines/Palm_EFB_Chopping_Machine.html

Palm EFB Processing Site

EFB Fiber Rotary Dryer

Although the whole EFB is chopped into short fiber by the chopping machine, the fiber would be blocked easily inside the rotary dryer. So we improved the feeding system, inside structure of the drum and output discharge system to prevent the blockage of the fiber and make sure the EFB fiber will flow smoothly and guarantee drying efficiency.

EFB Fiber Crusher

The EFB fiber crusher can crush the dried EFB fiber into small shorter fiber, which is suitable for the pelletizing. For processing the EFB fiber efficiently, we improved the hammers and screen. The head-saw hammers increase the crushing efficiency to the EFB fiber. The whole screen is separated into several individual parts; the customer do not need to change the whole screen, instead of just changing the individual wearing part.

Hammer Crusher Knives

Screen of Hammer Crusher

EFB Fiber Pellet Mill

Like the pretreatment of the EFB, we redesign feeding system of the pellet mill to prevent the blockage of the raw material. We know that the material blockage will damage the feeding system and influence the normal running of pellet mill.

With years of experience, we know the best compression ratio of the ring die, which is the key point to produce good quality EFB pellets. The ring die is made of specific high strength alloy stainless steel and through the carburization heat treatment to increase the hardness and wearability, which guarantees the durability.

The transmission gears through the heat treatment are imported from Germany, the main shaft and hollow shaft is made of high quality forging part, CNC high precision machining, which makes sure the stable operation.

The pellet mill is also equipped with automatic lubrication system to the main shaft and the bearings of the rollers, which improves the working efficiency and save labors. SPM780 pellet mill is also equipped with automatic oil cooling and lubrication system to the transmission gearbox.

Thanks to the optimized transmission structure, our SPM780 pellet mill can produce 2.5-3 TPH EFB pellets with around 150 KWH/Hour power consumption.

The auto adjustable feeding system and the operation security system makes sure the safety of the operators.

SPM780 Automatic Lubrication Sytem

Automated Grease Lubrication Sytem

Ring Die of SPM780 Pellet Mill

Roller of SPM780 Pellet Mill

EFB Pellet Cooling & Sifting System

The counter-flow cooler can reduce the temperature of the EFB pellets efficiently and fast, which makes the packed pellets harder and drier. The rotary sifter can sift the unformed stuff from the final pellet product efficiently.

After-sales Services

SIMEC has a complete after-sales service system to provide fast and professional assistance and make sure pellet plant in good running condition. We have the most professional technician teams to help our clients complete the installation and commissioning of the EFB pellet project. After that, our technician can stay on site to train our clients’ technicians for several months according to clients’ requirements.

Marketing Assistance

Besides providing technology & equipment to the investors who want to convert palm EFB into palm EFB pellets, SIMEC can also introduce the market of EFB pellets to the investors.

We are sincerely committed to providing our clients with the most appropriate proposal, reliable equipment and acceptable services.