Chlorella Vulgaris Biochar Experiment

Microalgae are a diverse group of aquatic, photosynthetic organisms, which are typically unicellular. As a new type of energy crop, microalgae have many advantages over other feedstocks, such as impressive productivity, noncompetition with agriculture, flexibility on water quality, mitigation of CO2, and broad product portfolio.

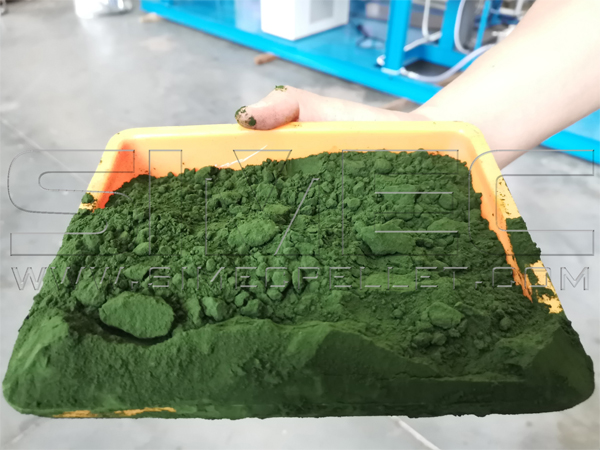

Product Name: Chlorella Powder Latin Name: Chlorella Vulgaris

Batch Number: CP0420230420 Date of Production:20230420

Shelf Life: three years Expiry Date: 20260419

Plant Part: Whole plant

| Test Items | Standard | Results | Test Methods |

| Appearance | Fine Uniform Powder | Complies | Visual |

| Protein | ≥50% | 56.3% | GB5009.5-2010 |

| Colour | Blue Green To Green | Complies | Visual |

| Chlorophyll | ≥1% | 1.5% | SNT 1113-2002 |

| Moisture | ≤7% | 3.9% | GB5009.3-2016 |

| Ash | ≤8% | 4.7% | GB5009.4-2016 |

| Pb | ≤1 ppm | 0.10 ppm | GB 5009.12-2017 |

| As | ≤1 ppm | 0.17 ppm | GB 5009.11-2003 |

| Cadmium | ≤0.2 ppm | 0.02 ppm | GB 5009.15-2014 |

| Hg | ≤0.1ppm | 0.01 ppm | GB 5009.17-2003 |

| Total Bacteria | ≤100,000cfu/g | 10,000 | GB 4789.2-2010 |

| Coliforms | Not detected | Not detected | GB_4789[1].3-2010 |

| Yeast and Mould | ≤1000cfu/g | <90cfu/g | GB 4789.15-2010 |

| Staphylococcus | Not detected | Not detected | GB 4789.10-2010 |

| Salmonella | Not detected | Not detected | GB 4789.4-2010 |

| Shigella | Not detected | Not detected | GB 4789.5-2003 |

| Mesh | 100% through 80 mesh | Complies | |

| To store at 0℃-20℃ and to avoid light and heat. | |||

Purposes and Objectives of Test Work:

1.Understand mass balance on difference process in order to understand Yield of biochar from a given amount of algae.

2.Biochar samples produced from the three strains of algae. At least 0.5 Kg of each sample.

3.Three sample of the bio-oil produced from the three strains of algae.

4.System data generated during operation of the pyrolysis unit, including reaction temperature, retention time, gas volume, gas composition, pressure, etc.

Date 1st August, 2023

Experimental Equipment: biomass pyrolysis laboratory apparatus designed by SIMEC.

Raw Material: Chlorella powder, moisture content less than 7%, bulk density 0.4-0.5 g/cm3.

Pyrolysis Temperature: 300 degree Celsius.

Residence Time: 20 minutes.

Weight Before Pyrolysis, Weight After Pyrolysis, and Yield of Biochar is confidential and not permitted to be disclosed to public.

Features of Biochar: dark green color, in the form of both chunks and powder. The chunks are hard but can be pressed to crack by hand. There’s a pungent smell.

Yield of Bio-oil is confidential information.

Features of Bio-oil: a viscous liquid of dark brown color; It emits a very pungent odor, which is easily volatilized into the surrounding air, and immediately causes extreme discomfort in the nasal cavity and eyes after inhalation.

Yield of Gases and Gas Composition is confidential and not permitted to be disclosed to public.

Gas pressure inside the carbonization reactor is regulated to be minus 0.1 Kpa. Gas temperature is 34.5 degree Celsius after condensation.

The 2nd Run of Chlorella Vulgaris Carbonization was on 8th August, 2023. The 3rd Run was on 18th August, 2023, using the same biomass pyrolysis laboratory apparatus designed by SIMEC.

Through the tests, it can be confirmed the production yield of algae based biochar is much higher than woody biomass. We will continue to explore its feasibility in commercial projects.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.