Palm EFB Leaching Pre-treatment for Bioenergy

It is well known that palm EFB has a high content of potassium and chlorine. When using the palm EFB for thermal conversion, excessive content of potassium and chlorine will cause the boiler corrosion, and the ash will have lower melting temperature and turned to causing slagging and agglomeration. Therefore, reducing the potassium and chlorine content in palm EFB becomes one of the most critical steps to make full use of palm EFB. SIMEC technology is developed to make high quality palm EFB pellets for co-firing in power plant.

The following table compares the content of several elements in palm EFB with the standard content of thermal conversion:

The following table compares the content of several elements in palm EFB with the standard content of thermal conversion:

| Element | Typical content | Standard content of thermal conversion |

|

Chlorine (Cl) |

0.3 to 2% of dry EFB | <0.02% |

|

Potassium (K) |

0.6 to 2% of dry EFB |

Difficult to quantify

but<0.03% K+Na is sometimes mentioned

|

|

Sodium (Na) |

0 to 1% of dry EFB |

Difficult to quantify but<0.03% K+Na is sometimes mentioned |

| Ash | 1 to 15% | 0.5 to 3.5% |

It can be seen from the table that the content of potassium and chlorine in palm EFB is higher than the standard content of thermal conversion.

Therefore, the content of potassium and chlorine should be reduced to the usable range through some processing methods.

Usually, the content of chlorine and potassium in palm EFB decreases by 90% and 80% after consecutive free-flowing leaching, but it will consume a lot of water.

SIMEC counter current leaching can effectively reduce the chlorine and potassium content in palm EFB at an extremely low water consumption.

SIMEC CC Leaching of Palm EFB

Oil Palm EFB

It is difficult to realise a counter current flow of solids against the liquid flow.

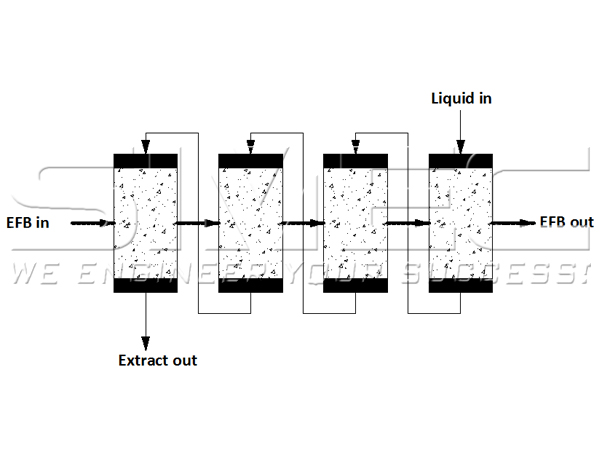

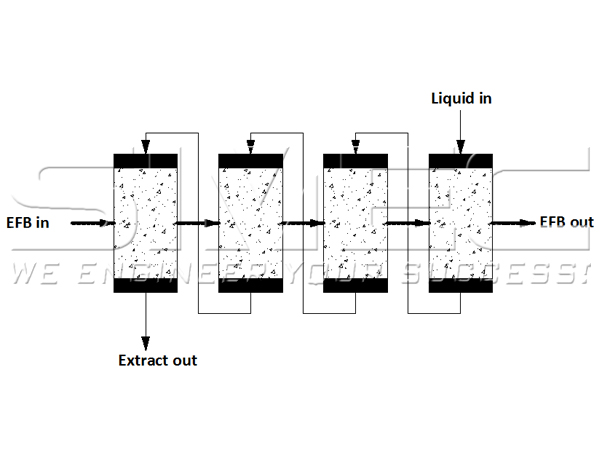

In order to solve this problem, firtsly, the palm EFB will be crushed into short fibers by hammer mill, then the fibers will be soak in water, the EFB-water mixture will pass trhough four cleaning pools in turn. Fresh water get into the pool which has the lowest concentration of potassium and chlorine, and flow against the direction of EFB-water mixture flow, and finally discharged from the pool with the highest concentration of potassium and chlorine where the leaching process starts. The whole process lasted about 30 minutes.

This leaching process can reduce the content of potassium and chlorine in palm EFB by 90% with the least water consumption.

Moreover, it is estimated that the cost of reducing potassium and chlorine content by SIMEC counter current leaching for 40,000 tons of palm EFB raw materials per year is about $2 per ton.

Therefore, the content of potassium and chlorine should be reduced to the usable range through some processing methods.

Usually, the content of chlorine and potassium in palm EFB decreases by 90% and 80% after consecutive free-flowing leaching, but it will consume a lot of water.

SIMEC counter current leaching can effectively reduce the chlorine and potassium content in palm EFB at an extremely low water consumption.

SIMEC CC Leaching of Palm EFB

Oil Palm EFB

It is difficult to realise a counter current flow of solids against the liquid flow.

In order to solve this problem, firtsly, the palm EFB will be crushed into short fibers by hammer mill, then the fibers will be soak in water, the EFB-water mixture will pass trhough four cleaning pools in turn. Fresh water get into the pool which has the lowest concentration of potassium and chlorine, and flow against the direction of EFB-water mixture flow, and finally discharged from the pool with the highest concentration of potassium and chlorine where the leaching process starts. The whole process lasted about 30 minutes.

This leaching process can reduce the content of potassium and chlorine in palm EFB by 90% with the least water consumption.

Moreover, it is estimated that the cost of reducing potassium and chlorine content by SIMEC counter current leaching for 40,000 tons of palm EFB raw materials per year is about $2 per ton.

|

Potassium and Chlorine Content Before and After SIMEC CC Leaching |

|

| Content | EFB |

| K before | 2.05% |

| K after | 0.4% |

| Cl before | 0.38% |

| Cl after | 0.02% |

After leaching, the ash composition of palm EFB after combustion will decrease, while the ash melting temperature will increase , which makes the ash more difficult to slogging and agglomerate.

| Palm EFB | Before | After | |

| Ash (550℃) | (% of DW) | 4.64 | 1.85 |

| Ash(815℃) | (% of DW) | 3.77 | 1.73 |

| S | (% of DW) | 0.063 | 0.023 |

| Cl | (% of DW) | 0.38 | 0.024 |

| Na2O | (% of ash 815℃) | 2.93 | 0.78 |

| K2O | (% of ash 815℃) | 37.8 | 12.7 |

SIMEC Counter Current Leaching of palm EFB can reduce the potassium and chlorine content to the standard, thus protect the boiler from corrosion in heat conversion. It also reduce the slogging and agglomeration of ash and prolonging the boiler serve life. So as to obtain higher quality palm EFB pellets and to occupy a wider international market, leaching pretreatment of palm EFB is very important for palm EFB pellet manufacturers.

SIMEC palm EFB leaching system could be customized according to specific requirements on potassium and chlorine content. For more information, please contact info@simecpellet.com

SIMEC palm EFB leaching system could be customized according to specific requirements on potassium and chlorine content. For more information, please contact info@simecpellet.com