Location Guide of Palm EFB Pellet Plant

As a kind of by product in crude palm oil (CPO) mills, Empty Fruit Bunch is trying to change its label from “Waste” to “Wealth”. That benefits from SIMEC Pelletizing Technology which is developed to utilize palm EFB which contains high moisture fibers. As is known to all, palm EFB pellets are very good solid fuel for biomass power plants and industrial boilers. Pellets are much easier to be transported and stored than palm EFB and fiber.

Fresh palm EFB storage pile will generate peculiar smell and effluents. Many CPO mills pay high costs to dispose palm EFB by transportation and landfill. But soon, this solution may not even be allowed because of environmental protection policy. Such problems must be solved by better waste treatment solution.

Fresh Palm Empty Fruit Bunch

Processed Palm EFB Fiber

Good news is, nowadays, palm EFB pellets have been preferred by Biomass Power Plants as economic and ECO-friendly bio-fuels. Performance of palm EFB pellets has been approved by long term field combustion tests.

Therefore, it is a wise decision for investors to establish palm EFB pellet plant, and also a good chance to change plam EFB from “waste” to “wealth”.

Considering high moisture content of palm EFB itself, transportation cost of palm EFB is the prior factor which impacts the benefit of palm EFB pellet project mostly. A good location choice is really helpful for achieving success of palm EFB pellet plant. Based on our experience, we shall offer guides in three general sections (According to three situations):

The First Location: Inside Palm Oil Mills

Similar to the locations of Crude Palm Oil Mills which are mostly located inside oil palm plantations, a palm EFB pellet plant can be located in or next to crude palm oil mills naturally.

Fresh palm EFB storage pile will generate peculiar smell and effluents. Many CPO mills pay high costs to dispose palm EFB by transportation and landfill. But soon, this solution may not even be allowed because of environmental protection policy. Such problems must be solved by better waste treatment solution.

Fresh Palm Empty Fruit Bunch

Processed Palm EFB Fiber

Therefore, it is a wise decision for investors to establish palm EFB pellet plant, and also a good chance to change plam EFB from “waste” to “wealth”.

Considering high moisture content of palm EFB itself, transportation cost of palm EFB is the prior factor which impacts the benefit of palm EFB pellet project mostly. A good location choice is really helpful for achieving success of palm EFB pellet plant. Based on our experience, we shall offer guides in three general sections (According to three situations):

The First Location: Inside Palm Oil Mills

Similar to the locations of Crude Palm Oil Mills which are mostly located inside oil palm plantations, a palm EFB pellet plant can be located in or next to crude palm oil mills naturally.

Palm EFB Conveyed from CPO Mills

Palm EFB Transported by Conveyor

This type of location is fit for small scale palm EFB pellet plant whose capacity is decided by the output capacity of CPO mill itself. Palm EFB pellet plant can share some infrastructures with CPO mill, such as sewage pools, power supply and so on. Single barrel EFB press which is able to separate mixture of water & oil from fresh palm EFB and reduce its moisture from 65% down to 55% is recommended also. You can collect 2.5% residue oil from the mixture again.

The Second Location: Nearby Several Crude Palm Oil Mills

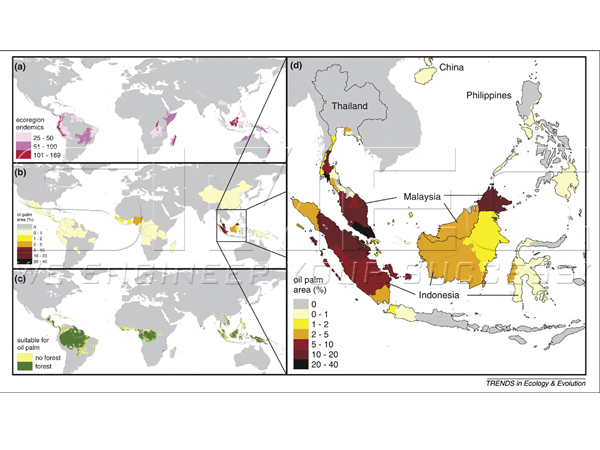

Being the countries in the first camp of Palm Oil exporting, Malaysia and Indonesia own the largest Oil Palm plantations over the world. Due to the intensive cropping system of palm trees shown as below diagram, it means the CPO mills are highly centralized, too.

Crushed Palm EFB Fiber

Palm EFB Fiber at Storage

The Third Location: Nearby or Inside Sea Port District

Planned site of Palm EFB Pellet Plant and Storage in Sea Port:

It is an optional choice to build pellet plant and pellet storage silos in sea port district. Same as other bulk cargoes, palm EFB pellets can be shipped by vessel directly. A long distance conveyor connects dock and pellet silos. Once the vessel comes, it can be filled within 2~3 days efficiently. The only limit of palm EFB pellet production in sea port district is the strict drainage policy. So it requires to reduce moisture of EFB in CPO Mills. Same solution as the second Guide Section.

An outstanding location choice of palm EFB pellet plant is a good beginning of the entire project. Advanced technology, quality equipment and professional after service decide the final success of project indeed. SIMEC is able to offer complete solution and consultant service to help investors start up palm EFB pellet plants successfully.

We engineer your success!