Causes of Current Instability in Pellet Mill

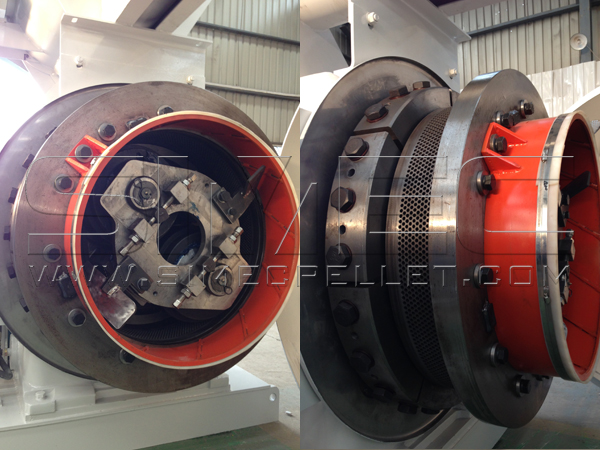

During the biomass pellet production process, ring die and rollers of pellet machine rotate at a constant speed, when the feeding quantity is equal to the discharging quantity, the energy consumption is steady, and the current remains stable. But sometimes the current is unstable while pellet machine working, what is the cause of it?

According to the production experience, reasons for unstable current of pellet machine are mainly the following three:

According to the production experience, reasons for unstable current of pellet machine are mainly the following three:

1. When the feeding quantity is larger than the discharging quantity, that is to say, part of the material will remain inside the machine. While the machine is running, it will inevitably work on this part of the material, increasing the energy consumption of the machine and increasing the current.

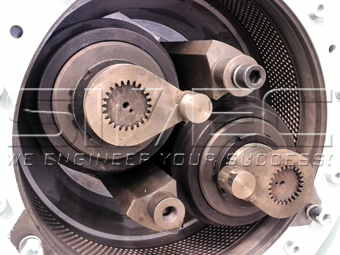

2. The material feeding scraper is badly worn, which results in uneven material distribution. Under this condition, the uneven feeding of the press roller will cause the current to become unstable.

3. Raw material contains hard impurities, such as iron or stone. Equipment extrusion pressure increases due to the press rollers rotate at the position of the stone or iron, causing the current increases suddenly, after the impurities get through this position, current will drop down.

2. The material feeding scraper is badly worn, which results in uneven material distribution. Under this condition, the uneven feeding of the press roller will cause the current to become unstable.

3. Raw material contains hard impurities, such as iron or stone. Equipment extrusion pressure increases due to the press rollers rotate at the position of the stone or iron, causing the current increases suddenly, after the impurities get through this position, current will drop down.

Knowing the reasons for the instability of the biomass pellet machine current, operators can find and solve the problems in the process of biomass pellet production more quickly, and can maximize the production.